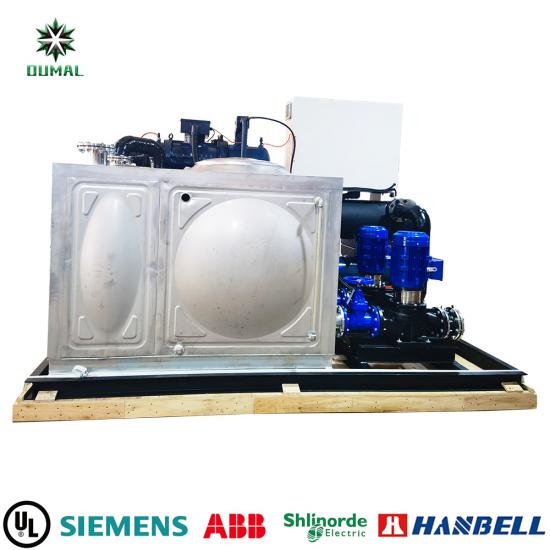

60Ton Screw Type Water Chiller System For Industrial Processing Cooling

A water chiller system is a cooling system that uses water or a water-based solution as a cooling fluid to remove heat from a process or building, then dissipates the heat to the atmosphere. These systems are used for large-scale air conditioning in buildings and for industrial applications like manufacturing, and they work using a refrigeration cycle to cool the water, which is then pumped to where cooling is needed.

This water cooled screw chiller package unit is an integrated industrial cooling unit containing a water cooled screw chiller, water pump, water tank and control panel. The integrated water-cooled chiller is easy to install and easy to operate, greatly lowering installation cost. The chiller & Tank & Pump all in one packaged kits, Client Only need to connect the user and the cooling tower, Use Siemens PLC Controller, Components with UL Certificate, Factory installed the pipes, Easy installation.

Advantages of skid-mounted screw chiller units

*** All in One

*** Compact

*** Reliable

*** No piping Error

*** No wiring Error

*** Simple installation

*** Save time

*** Save labor cost

Detail advantage Features of the water chiller system

1. Integrated Design

The water chiller system integrates the compressor, condenser, evaporator, control system, cooling water pump, chilled water pump, expansion tank, and various valves and controllers of the refrigeration unit into one unit. This simplifies and speeds up installation and commissioning, saves installation space, and reduces on-site engineering complexity.

2. Cost Savings Integrated Control: The unit integrates the control of engineering components and the refrigeration unit, reducing the number of electrical control boxes, increasing control stability, and lowering costs. Compact Structure: The unit has a compact structure, occupies little space, and can be flexibly placed to adapt to various installation environments.

3. High Efficiency and Energy Saving High-Efficiency Components: The unit uses a twin-screw compressor, matched with a high-efficiency condenser, evaporator, and imported expansion valve, achieving an overall energy efficiency rating of level 3 or higher, improving energy utilization efficiency.

4. Reliable Operation and Safety Protection: The unit has 7 safety protection measures to ensure stable operation under various operating conditions. In the case of a dual-circuit and dual-compressor design: when one compressor fails, the other compressor can still operate normally, ensuring continuity of use for the customer.

5. Intelligent Management & Microcomputer Control System: The unit adopts a Siemens PLC control system with a user-friendly interface, providing timely feedback on maintenance information and improving management efficiency. Central Control System Connection: The unit's control system can be connected to the user's central control system, allowing customers to monitor the unit's operation remotely and comprehensively at any time.

6. Multiple Refrigerant Options to Meet Customer Needs: The unit can provide refrigerants such as R407C and R134a to meet the specific needs of different customers.

In summary, integrated water-cooled screw chiller units offer significant advantages in terms of ease of installation, cost savings, high energy efficiency, operational reliability, intelligent management, and refrigerant selection, making them the preferred solution for refrigeration equipment engineering installations.

Water cooled screw chiller Product display

Compressor features:

•New screw type compressor with 20%-30% higher in efficiency.

•Cooling capacity control available at four steps (100%-75%-50%-25%), three steps (100%-66%-33%) or no steps control system.

•High efficiency, low noise and vibration, easy to install.

•Environmental protection refrigerant R134a, R407c available.

Control operation system:

•SIEMENS PLC program control system, human-computer interface with big LED touch panel, running state displaying in multi-language, and self-diagnosis for easy operation and supervision.

•Extended industrial interface, convenient for being computer monitor via network.

Completely safety protection function:

•Multi-safety protection by high and low pressure, compressor overheating, overloading, over temperature, flow switch, phase sequence, phase-missing, exhaust overheating and anti-freezing.

60 Ton Water Cooled Screw Chiller Application

Industrial cooling water systems are commonly used in various industries, including power plants, chemical processing plants, refineries, manufacturing facilities and data centers to remove excess heat generated during production processes and equipment operation to ensure safe and efficient operation.

50 Ton Screw chiller Product Specification

|

Item Model |

OMC-60WSH |

||

|

Cooling Capacity |

kcal/h |

173376 |

|

|

KW |

201.6 |

||

|

Ton |

57.3 |

||

|

Btu/h |

688055 |

||

|

Input Power |

KW |

42.3 |

|

|

Max.running Current |

A |

112 |

|

|

Power supply |

|

3PH-380V/415V 50HZ(220V/440V 60HZ)) |

|

|

Refrigerant |

Type |

|

R22 |

|

Charge quantity |

kg |

42 |

|

|

Control Mode |

|

Expansion Valve |

|

|

Compressor |

Type |

|

Semi-Hermetic Screw |

|

Power |

KW |

42.3 |

|

|

Start-up Mode |

|

Y-△ |

|

|

Capacity Control |

% |

0-25-50-75-100 (0-33-66-100) |

|

|

Evaporator |

Type |

|

Shell and Tube |

|

Chilled water flow |

m3/h |

34.7 |

|

|

Pipe Diameter |

lnch |

3" |

|

|

Condenser |

Type |

|

Shell and Tube |

|

Cooling water flow |

m3/h |

42.0 |

|

|

Pipe Diameter |

lnch |

3" |

|

|

Dimension |

Length |

mm |

2450 |

|

Width |

mm |

985 |

|

|

Height |

mm |

1600 |

|

|

Net Weight |

kg |

1120 |

|

|

Running Weight |

kg |

1270 |

|

|

Safety Protection:Compressor over temperature protection, over load protection, high and low pressure protection, anti-freezing protection, reversed and lacking phase protection, fusible blug, flow switch |

|||

Packing & Shipping

FAQ

Q1: Could you help us to recommend the model for our project?

A1: Yes, we have engineer to check the details and make the scheme for you. Based on the following:

1)Cooling capacity;

2)chilled water inlet and outlet temperature

3)chilled water flow

4) Refrigerant;

5) Ambient temperature;

6)Voltage;

7) Be used for what industry?

8)Any other special requirements?

Q2: How to ensure your product with good quality?

A2: All our products with CE certificate. And use the well-know brand accessories, such as Copeland, Danfoss,Hanbell, Bitzer compressor Emerson expansion Valve, Siemens controller.

also can be customized. All OUMAL Chillers are factory tested under load conditions to ensure good quality and easy installation for users

Q3: What's the warranty?

A3: 15 months warranty for free if confirmed by both side damage in the quality reason.

Q4: Whats your payment term?

A4: We accept T/T, LC, Western Union, etc. Normally, 30% deposit for production, 70% balance before shipment.

Q5: Are you a manufacturer?

A5: Yes, we have more than 15 years in water chiller business. Also have patent on the water chiller appearance.

The control box design make the unit safety and stably.

Q6: How can i Place an order

A6: Click Below to fill the table or Call 0086 15112554736

en

en es

es