40HP Customized Inverter water cooled chiller with 304SS frame

Inverter water-cooled chillers are highly efficient and energy-efficient refrigeration equipment that combine variable frequency speed regulation technology with a water-cooled heat dissipation system. They are widely used in industrial, commercial, and special environments. The following is a technical analysis of their core features:

1. Core Components and Principles

Variable Frequency Compressor: Utilizes a Danfoss variable frequency compressor, coupled with an onboard inverter, for stepless load regulation, significantly improving partial load energy efficiency. The frequency range is 3-100Hz, offering excellent low-frequency characteristics and high overload capacity.

Water Cooling System: Utilizing high-efficiency heat exchangers (such as flooded evaporators) and spray falling film technology, they optimize heat dissipation and withstand high temperature and humidity environments, making them suitable for extreme operating conditions such as military and metallurgical industries.

Intelligent Control: Utilizes a Siemens PLC control system that adaptively adjusts the compressor pressure ratio to avoid under- and over-compression losses. It supports ECO and sleep modes to reduce energy consumption.

2. Technical Advantages

Energy Saving and High Efficiency: Variable frequency drive reduces grid impact, and a wide voltage design (380V-440V) enhances grid adaptability, significantly improving partial-load energy efficiency.

Environmentally Friendly Refrigerant: Utilizes R410A, an environmentally friendly refrigerant that is ozone-safe and meets international environmental standards.

System Optimization: Computer simulation technology optimizes heat exchanger design, improving heat transfer efficiency by over 5%.

3. Application Scenarios

Industrial Applications: Applications such as sewage treatment, metallurgy, and chemical engineering require a stable operating environment that is corrosion-resistant and high-temperature resistant.

Commercial Buildings: Applications in central air conditioning systems in subways, hospitals, and shopping malls, balancing energy efficiency and comfort.

Specialty Requirements: The system can be equipped with expansion devices such as water-cooled brakes and encoders to meet diverse industrial needs.

Oumal customized inverter water-cooled scroll chiller featuring two Danfoss inverter compressors for optimal performance. This advanced chiller boasts a robust design with both the evaporator and condenser crafted from durable 304 stainless steel in a shell-and-tube configuration. Equipped with pumps featuring inverters and a Siemens PLC controller, it ensures precise temperature control for your specific needs. The entire chiller body is constructed from high-quality 304 stainless steel, guaranteeing strength, corrosion resistance, and easy maintenance.

Oumal Refrigeration specializes in industrial cooling solutions and offers tailored services facilitated by our skilled technical team. Contact us today to explore how our industrial chillers can meet your unique requirements and elevate your operations!

Inverter Water Cooled Chiller Product Information

Temperature control 5ºC to 35ºC

High quality 304SS Shell and tube evaporator and condenser

Build in Danfoss Inverter compressor

Refrigerant: R410A

Safety protection devices of whole screw chiller

Siemens PLC controller system With HDMI Touch Screen

304 Stainless Steel frame

Inverter chiller advantage

Variable frequency water-cooled chillers offer numerous advantages in industrial applications:

Energy Efficiency: Utilizing a variable frequency compressor, the operating frequency intelligently adjusts based on actual load, providing precise cooling and energy efficiency.

Precise Temperature Control: Equipped with a Siemens PLC controller, precise temperature control is achieved, ensuring stable production processes.

Durable Materials: The chiller body is constructed of 304 stainless steel, offering excellent strength and corrosion resistance, easy cleaning, and long-term stable operation.

Customized Services: Oumal Refrigeration has a professional technical team and can provide customized services, tailoring industrial chillers to meet individual customer needs.

Powerful Performance: Utilizing two Danfoss variable frequency compressors and equipped with a 304 stainless steel shell and tube evaporator and condenser, they deliver exceptional performance and reliability.

If you require an industrial cooling solution, please contact us and let Oumal Refrigeration customize a professional chiller for you.

Water Cooled Chiller Application

40HP Inverter water cooled chiller products Specification

|

Item Specification |

OMC-40W |

||

|

Cooling Capacity |

kcal/h |

103200 |

|

|

KW |

120 |

||

|

Ton |

34 |

||

|

Input Power |

KW |

30 |

|

|

Power supply |

|

3ph 460V-60Hz |

|

|

Chiller Casing Material |

|

304 Stainless steel |

|

|

Controller |

|

Siemens S7-1200 one for backup |

|

|

Refrigerant |

Type |

|

R 410A |

|

Charge quantity |

kg |

25 |

|

|

Control Mode |

|

Electric Expansion Valve |

|

|

Compressor |

Type |

|

Inverter Type hermetic scroll type |

|

Power |

KW |

15* 2 |

|

|

Evaporator |

Type |

|

Stainless Steel Shell and Tube |

|

Chilled water flow |

m3/h |

20.6 |

|

|

Pipe Diameter |

inch |

3" |

|

|

Condenser |

Type |

|

Stainless Steel Shell and r Tube |

|

Cooling water flow |

m3/h |

25.8 |

|

|

Pipe Diameter |

inch |

3" |

|

|

Safety Protection |

Compressor over temperature protection, over load protection, high and low pressure protection, anti-freezing protection, reversed and lacking phase protection, fusible blug, flow switch |

||

|

Dimension |

Length |

mm |

2000 |

|

Width |

mm |

1000 |

|

|

Height |

mm |

1700 |

|

|

Net Weight |

kg |

1400 |

|

|

Running Weight |

kg |

1560 |

|

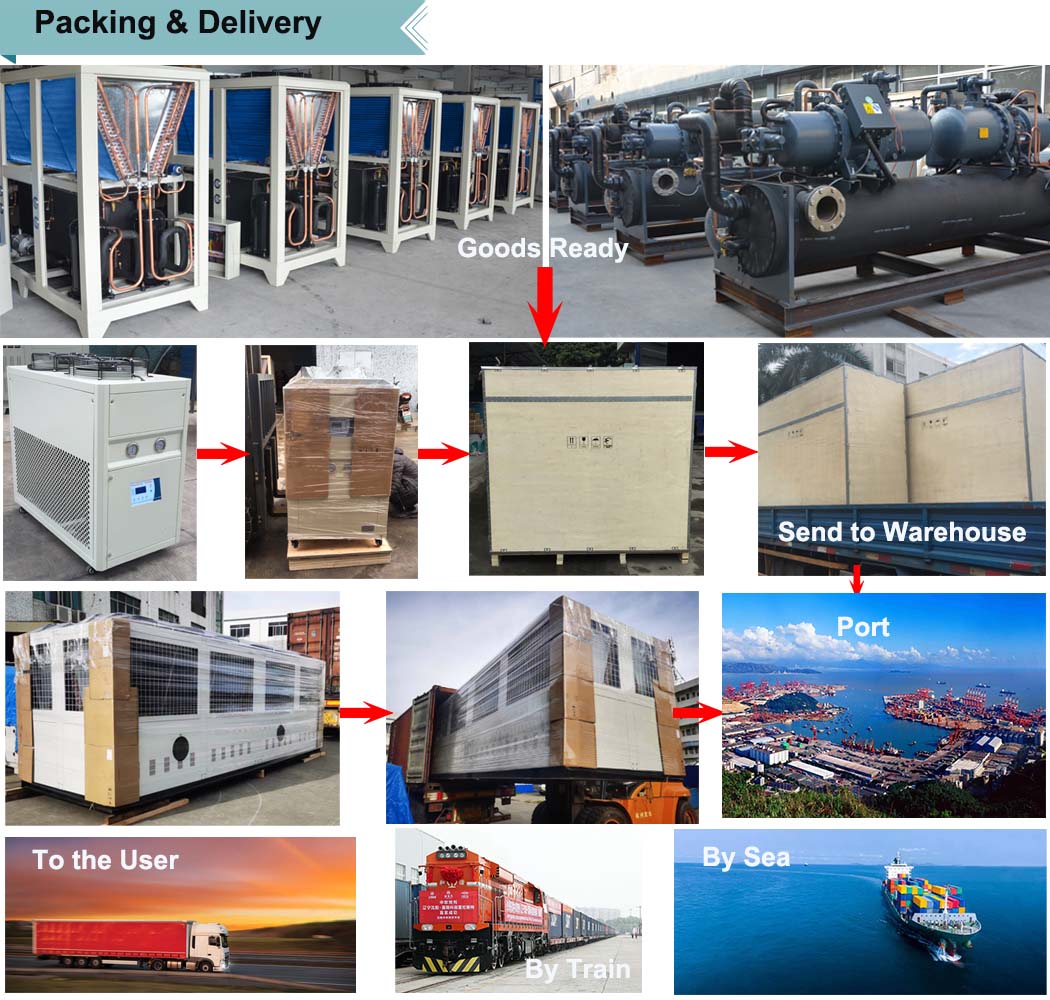

Package And Delivery

Lead time of the Inverter Chiller is 40-50 Working Days.

Shipping by sea with Plywood Package or fill packing in the container.

en

en es

es