30 ton / 100KW Glycol water chiller for chemical with 316SS shell and tube evaporator

Our 30-ton / 100KW Glycol Water Chiller is specifically tailored for chemical processes, offering efficient cooling solutions for a variety of industrial needs. With its robust design and reliable performance, this chiller ensures precise temperature control, making it ideal for maintaining the desired conditions in chemical production environments. Trust in this chiller to provide consistent cooling while meeting the demanding requirements of your chemical applications. This 100KW glycol chiller used Bitzer Screw Compressor, In order to make the unit anti-corrosion and increase the service life of the chiller, our evaporator uses a shell and tube evaporator made of 316 stainless steel. The controller system adopt Siemens PLC + HMI. Intelligent temperature control, easy to operate.

Glycol chillers are widely used in various industries due to their ability to control low-temperature processes effectively. Some common industries where glycol chillers find applications include:

Chemical Industry: Glycol chillers are essential in chemical processes requiring precise temperature control for reactions and equipment cooling.

Pharmaceutical Industry: In pharmaceutical manufacturing, glycol chillers help maintain controlled temperatures, crucial for the production and storage of sensitive medications.

Plastics Industry: Glycol chillers are used in injection molding, extrusion, and other plastic processes to cool molds and maintain consistent temperatures for quality production.

Brewing and Beverage Industry: Glycol chillers play a vital role in breweries and beverage production by regulating fermentation temperatures and cooling storage tanks.

Food Processing: In food industries, glycol chillers are utilized for various applications such as cooling during processing, storing perishable goods, and maintaining food safety standards.

HVAC Industry: Glycol chillers are employed in HVAC systems for air conditioning, cooling buildings, and regulating indoor climate control.

Medical and Laboratory Equipment: Glycol chillers are used to cool medical imaging equipment like MRI machines, CT scanners, and laboratory instruments that require precise temperature management.

Overall, the versatility and efficiency of glycol chillers make them indispensable in various industrial sectors where temperature control is paramount to operational success and product quality.

Key features of our Glycol water chiller include:

High Cooling Capacity: With a powerful 100kw cooling capacity, it effectively meets the demands of industrial applications.

Energy Efficiency: The chiller utilizes advanced technologies to optimize energy consumption, reducing operating costs and environmental impact. Compressor adopt Bitzer screw type compressor, high quality and high efficient.

Reliable Performance: Built with durable components, the chiller ensures long-lasting and trouble-free operation, minimizing downtime and maximizing productivity. Evaporator adopt 316 Stainless Steel shell and tube.Corrosion protection and long lifetime.

Precise Temperature Control: Equipped with a sophisticated control system, the chiller maintains a stable and accurate temperature range, safeguarding the quality and consistency of your production. Controller system adopt Siemens PLC controller and HMI. Easy installation.

Easy Maintenance: The chiller's user-friendly design simplifies regular maintenance tasks, allowing for convenient upkeep and extending the service life of the equipment.

In summary, our 30 ton water-cooled glycol chiller offers a powerful and efficient cooling solution for a range of industrial applications. With its reliable performance, energy efficiency, and precise temperature control, it is an ideal choice for plastic extrusion, PVC pipe production, and various other cooling needs in industrial settings. Experience optimum cooling performance and maximize your production capabilities with our dependable water-cooled screw chiller.

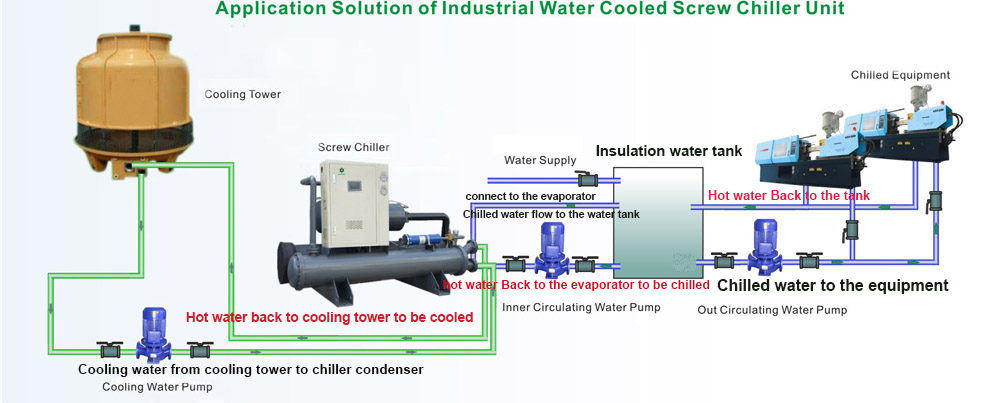

Water-Cooled Design: The chiller uses water as the cooling medium, which is circulated through the system to remove heat from the industrial processes. It requires a water source and a cooling tower or an external water-cooling system.

Control System: The chiller is equipped with an advanced control system that allows for precise temperature control and operational settings. It may include features such as programmable logic controllers (PLCs), touch-screen displays, and remote control capabilities.

Safety Features: The chiller may come with various safety features, such as high/low-pressure protection, motor overload protection, anti-freezing protection, and phase sequence protection, ensuring safe and reliable operation.

Energy Efficiency: The chiller is designed to be energy-efficient, with features like variable frequency drives (VFD) and intelligent control algorithms that optimize the chiller's energy consumption and reduce operational costs.

Robust Construction: The chiller is built with durable materials and a robust construction to withstand the demands of industrial environments. It is designed for continuous operation and requires minimal maintenance.The 70 ton water cooled chiller use high quality semi-hermetic screw compressor Bitzer or Hanbell. Single and double compressors system optional.

Advantages of the water cooled screw chiller

Water cooled screw chillers offer several advantages in industrial cooling applications:

Cooling Efficiency: Water cooled chillers are known for their cooling efficiency. They can maintain precise and stable temperature control, making them suitable for applications that require consistent cooling performance.

High Capacity: Water cooled screw chillers often have higher cooling capacities compared to their air cooled counterparts. This makes them suitable for cooling large industrial processes or equipment that generate high heat loads.

Energy Efficiency: Water cooled chillers can achieve higher energy efficiency due to the use of water as a cooling medium. They use less energy compared to air cooled chillers because water has higher heat transfer efficiency.

Reduced Noise Levels: Since the cooling is done using water, the noise levels of water cooled screw chillers are generally lower compared to air cooled chillers. This makes them more suitable for industrial environments where noise is a concern.

Flexibility in Installation: Water cooled chillers offer flexibility in installation as they can be placed indoors or outdoors. They require a separate water cooling tower or a water source for the heat exchange process.

Longer Service Life: Water cooled screw chillers typically have a longer service life compared to air cooled chillers. This is because water cooling helps maintain lower operating temperatures, reducing wear and tear on the compressor and other components.

Environmentally Friendly: Water cooled chillers are considered more environmentally friendly due to their higher energy efficiency, which results in lower greenhouse gas emissions compared to air cooled chillers.

It's important to note that water cooled screw chillers require proper water treatment and maintenance to prevent scaling, corrosion, and bacteria growth in the system. Regular maintenance and monitoring are necessary to ensure optimal performance and longevity of the chiller.

Water cooled Glycol chiller is a specially designed cooling unit which can work efficiently even in an extreme tropical environment. It maintains consistent heat dissipation by chilled water of the condenser. Cooling tower is used together with the water cooled screw chiller. Here is the 60 HP water cooled screw chiller glycol chiller connection:

If you are looking for a glycol water chiller, please call us to get the latest water cooled screw chiller price. Other cooling capacity of the chillers are welcome. OUMAL CHILLER have experienced technical team, will provide the best cooling water system for your industrial cooling.

Screw compressor Glycol water chiller Product Information

●:Temperature control -35℃ to 0℃

●:Shell and tube evaporator and condenser

●:Bizer or Hanbell semi-hermetic screw compressor

●:Optional refrigerant R134a,R407c and R404a

●:Schneider Electrical Components

●:PLC/ Touch Screen Control Panel

●:No water tank, connect an external water tank

●:Need to connect a cooling tower

●:Safety protection devices of whole screw chiller

●:All models and cooling capacity available

Screw type water chiller Product display

Compressor features:

•New screw type compressor with 20%-30% higher in efficiency.

•Cooling capacity control available at four steps (100%-75%-50%-25%), three steps (100%-66%-33%) or no steps control system.

•High efficiency, low noise and vibration, easy to install.

•Environmental protection refrigerant R134a, R407c available.

Control operation system:

•SIEMENS PLC program control system, human-computer interface with big LED touch panel, running state displaying in multi-language, and self-diagnosis for easy operation and supervision.

•Extended industrial interface, convenient for being computer monitor via network.

Completely safety protection function:

•Multi-safety protection by high and low pressure, compressor overheating, overloading, over temperature, flow switch, phase sequence, phase-missing, exhaust overheating and anti-freezing.

Screw Water Chiller Application

100kw screw type glycol water chiller is widely used in plastic such as extrusion cooling system, Injection molding cooling water system, blowing machines cooling water system. Also can used in concrete mixing cooling water system. Medical industry cooling water system. Chemical chilled water system,etc.

100kw Glycol chiller Product Specification

| Item | Model | OMC-60WSL | |

| Cooling Capacity | kcal/h | 95,202 | |

| KW | 110.7 | ||

| Ton | 31.5 | ||

| Input Power | KW | 47.4 | |

| Max. running Current | A | 79.2 | |

| COP | 2.34 | ||

| Power Supply | 3PH-400V 50HZ | ||

| Refrigerant | Type | R404A | |

| Charge quantity | kg | 35 | |

| Control Mode | Expansion Valve | ||

| Compressor | Type | Semi-Hermetic Screw | |

| Power | KW | 47.4 | |

| Start-up Mode | Y-△ | ||

| Capacity Control | % | 0-25-50-75-100 | |

| Evaporator | Type | Dry type 316SS Shell and 316SS Tube | |

| Chilled water flow | m3/h | 19 | |

| Pipe Diameter | inch | DN80 | |

| Condenser | Type | Dry type Carbon steel Shell and Copper Tube | |

| Cooling water flow | m3/h | 27 | |

| Pipe Diameter | inch | DN50 | |

| Safety Protection | Compressor over temperature protection, over load protection, high and low pressure protection, anti-freezing protection, reversed and lacking phase protection, fusible blug, flow switch | ||

| Dimension | Length | mm | 2450 |

| Width | mm | 985 | |

| Height | mm | 1600 | |

| Net Weight | kg | 1300 | |

| Running Weight | kg | 1450 | |

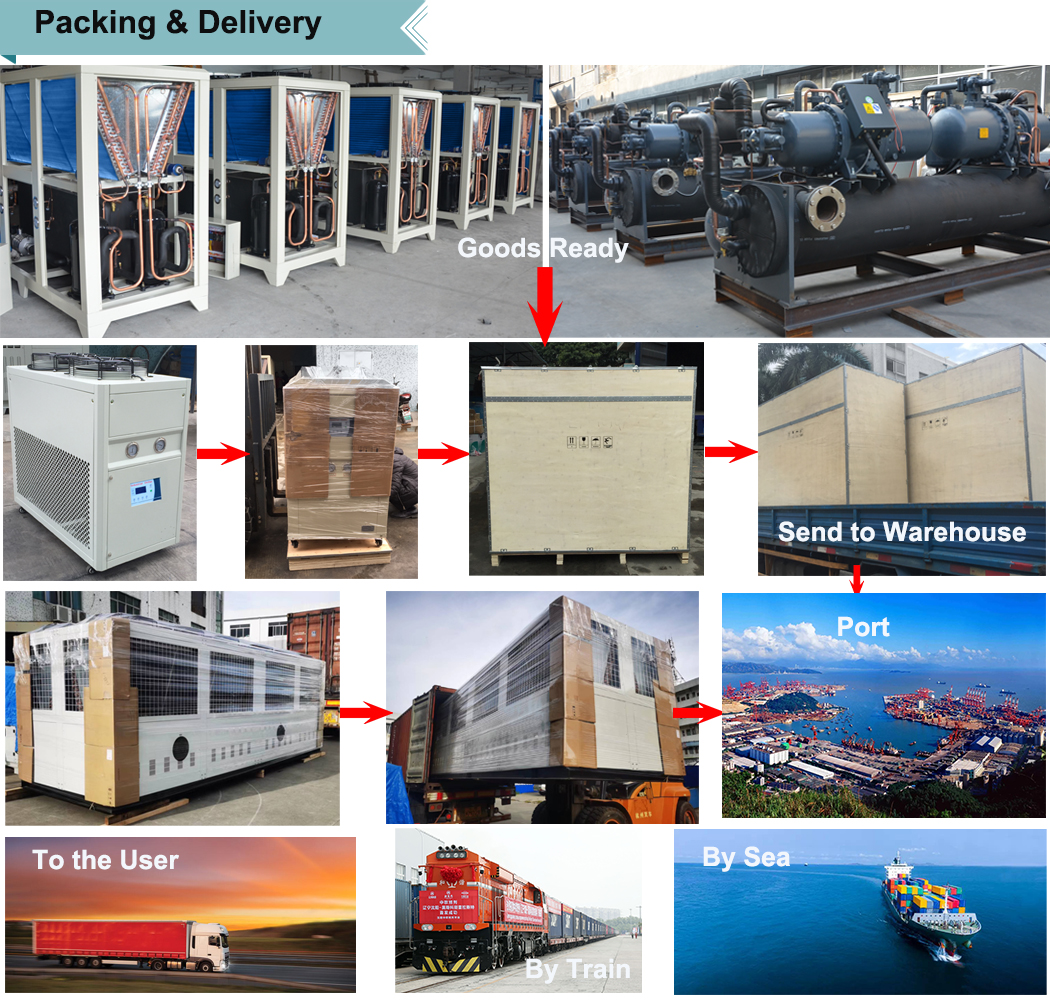

Packing & Shipping

FAQ

Q1: Could you help us to recommend the model for our project?

A1: Yes, we have engineer to check the details and make the scheme for you. Based on the following:

1)Cooling capacity;

2)chilled water inlet and outlet temperature

3)chilled water flow

4) Refrigerant;

5) Ambient temperature;

6)Voltage;

7) Be used for what industry?

8)Any other special requirements?

Q2: How to ensure your product with good quality?

A2: All our products with CE certificate. And use the well-know brand accessories, such as copeland, danfoss,Hanbell, Bitzer compressor Emerson expansion Valve, Siemens controller.

also can be customized. All OUMAL Chillers are factory tested under load conditions to ensure good quality and easy installation for users

Q3: What's the warranty?

A3: 15 months warranty for free if confirmed by both side damage in the quality reason.

Q4: Whats your payment term?

A4: We accept T/T, LC, Western Union, etc. Normally, 30% deposit for production, 70% balance before shipment.

Q5: Are you a manufacturer?

A5: Yes, we have more than 15 years in water chiller business. Also have patent on the water chiller appearance.

The control box design make the unit safety and stably.

Q6: How can i Place an order ?

A6: Click Below to fill the table or Call 0086 15112554736

en

en es

es