400kw 110Ton Water Cooled Glycol Chiller with double Bitzer Screw Compressors

Industrial chillers, also known as water chillers, water cooling chillers, chilled water machines, or cold water machines, are industrial devices that use vapor compression/absorption cycles for refrigeration. They are mainly used in production cooling and temperature control processes in industries such as machining, chemicals, pharmaceuticals, and new energy. Their core components include a compressor, evaporator, and condenser, and they are divided into two types by different condenser type: water-cooled (requiring a cooling tower) and air-cooled (for easy movement). With different compressor types, it also can be divided to scroll chillers , screw chillers, and piston chillers (Reciprocating chillers) . Industrial screw water chiller is an efficient and reliable industrial chiller unit.

The water cooled screw chiller is open type water chiller, it including a semi-hermetic screw compressor and a shell and tube condenser & Evaporator, a electricity box with controller systems. We use PLC controller. When you install a water cooled screw chiller, you need to use an external water tank and usully 3 pumps for the water cooled screw chiller system. The most important is that you need to connect a cooling tower to the chiller condenser for Heat dissipation. Compare with the air cooled screw chiller, the water cooled chiller is high efficient. but not easy to install. If you do not know how to install a water cooled screw chiller, you also can buy our Integrated water-cooled screw chiller machine.

Here are some key features and advantages of water-cooled screw chillers:

- Cooling System: Water-cooled screw chillers utilize a refrigeration system that consists of a compressor, evaporator, condenser, and expansion valve. The compressor compresses the refrigerant, which then flows through the evaporator where it absorbs heat from the process or the air conditioning system. The heated refrigerant is then sent to the condenser, where it releases heat to the cooling water. The water is circulated and cooled in a separate water loop.

-

High Cooling Capacity: Water-cooled screw chillers are capable of providing high cooling capacities, making them suitable for large-scale applications that require significant cooling capacity. They can handle a wide range of cooling loads and maintain precise temperature control.

- Energy Efficiency: Water-cooled screw chillers typically have better energy efficiency compared to air-cooled chillers. The water-cooled design allows for efficient heat transfer to the cooling water, resulting in lower energy consumption. Additionally, water-cooled chillers often have variable speed drive compressors that can optimize energy usage based on the cooling load.

- Low Noise Levels: Water-cooled screw chillers tend to produce lower noise levels compared to air-cooled chillers. The condenser, which is the component generating most of the noise, is located in a separate area with the cooling tower or other water-cooling equipment, effectively reducing noise in the immediate surroundings.

- Space Requirement: Water-cooled screw chillers typically require a dedicated cooling tower or external water source for heat dissipation. This design allows for smaller physical footprint compared to air-cooled chillers, which need space for the condenser fan unit.

-

Reliable Operation: Water-cooled screw chillers are known for their reliable operation and long service life. They are designed for continuous operation and can withstand high ambient temperatures and operating pressures. Regular maintenance and water treatment are essential to ensure efficient and reliable performance.

Oumal Chiller Projects

Products Specification

|

Item Model |

OMC-110WDL |

|||

|

Norminal cooling capacity |

Temp |

-3℃ |

397.6 |

|

|

Input Power |

KW |

67.6 * 2 |

||

|

Power Supply |

3PH-380V 50HZ |

|||

|

Refrigerant |

Type |

R22 (R404A) |

||

|

Control Mode |

Expansion Valve |

|||

|

Compressor |

Type |

Semi-Hermetic Screw |

||

|

Power |

KW |

67.6 * 2 |

||

|

Start-up Mode |

|

Y-△ |

||

|

Capacity Control |

% |

0-25-50-75-100 (0-33-66-100) |

||

|

Evaporator |

Type |

Temp |

304 SS Shell and Nickel Copper Tube |

|

|

Chilled water flow |

-3℃ |

m3/h |

68.4 |

|

|

Pipe Diameter |

Inch |

6” |

||

|

Condenser |

Type |

Shell and Tube |

||

|

Cooling water flow |

m3/h |

91.7 |

||

|

Pipe Diameter |

Inch |

6" |

||

|

Safety Protection |

Compressor over temperature protection, over load protection, high and low pressure protection, anti-freezing protection, reversed and lacking phase protection, fusible blug, flow switch |

|||

|

Dimension |

Length |

mm |

3750 |

|

|

Width |

mm |

1350 |

||

|

Height |

mm |

2150 |

||

|

Net Weight |

kg |

4230 | ||

|

Running Weight |

kg |

4560 |

||

The working principle of the water cooled screw chiller is: When the unit is refrigerated, the compressor sucks the low-temperature and low-pressure refrigerant in the evaporator into the cylinder. After the compressor performs work, the refrigerant vapor is compressed into high-temperature and high-pressure gas.

Enter the condenser through the exhaust pipe. The high-temperature and high-pressure refrigerant gas exchanges heat with the cooling water in the condenser, and transfers the heat to the cooling water, while the refrigerant gas is condensed into a high-pressure liquid. The high-pressure liquid from the condenser enters the evaporator after being throttled and pressure-reduced by the thermal expansion valve. In the evaporator, the low-pressure liquid refrigerant absorbs the heat of the chilled water and vaporizes, so that the chilled water is cooled down and becomes the required low-temperature water. The vaporized refrigerant gas is sucked in by the compressor again for compression, and discharged into the condenser, so that it goes round and round, and circulates continuously, so as to realize the cooling of the chilled water.

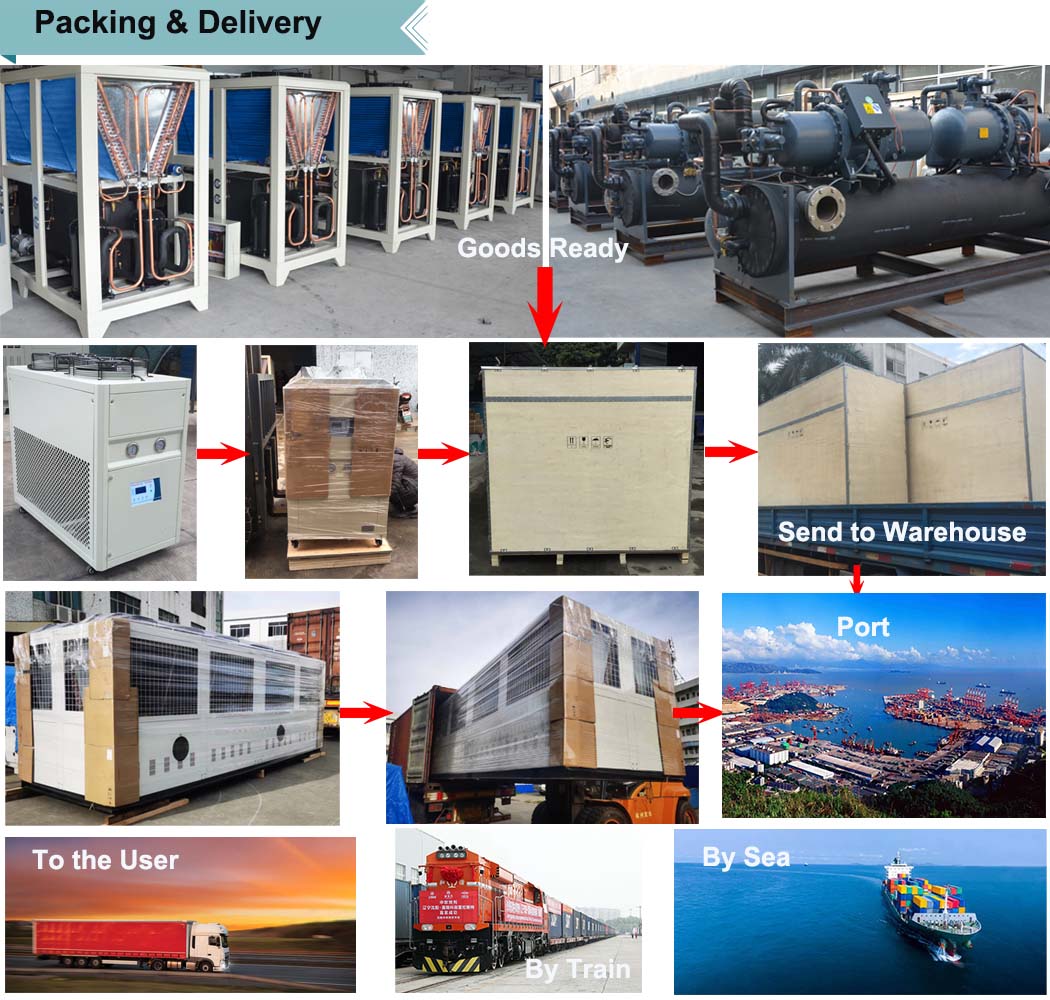

Packing & Shipping

FAQ

Q1:Could you help us to recommend the model for our project?

A1: Yes, we have engineer to check the details and make the scheme for you. Based on the following:

1)Cooling capacity;

2)chilled water inlet and outlet temperature

3)chilled water flow

4) Refrigerant;

5) Ambient temperature;

6)Voltage;

7) Be used for what industry?

8)Any other special requirements?

Q2:How to ensure your product with good quality?

A2: All our products with CE certificate. And use the well-know brand accessories, such as copeland, danfoss,Hanbell, Bitzer compressor Emerson expansion Valve, Siemens controller.

also can be customized. All OUMAL Chillers are factory tested under load conditions to ensure good quality and easy installation for users

Q3:What's the warranty?

A3: 15 months warranty for free if confirmed by both side damage in the quality reason.

Q4:What’s your payment term?

A4: We accept T/T, LC, Western Union, etc. Normally, 30% deposit for production, 70% balance before shipment.

Q5:Are you a manufacturer?

A5: Yes, we have more than 15 years in water chiller business. Also have patent on the water chiller appearance .

The control box design make the unit safety and stably.

Q6:How can i Place an order ?

A6: Click Below to fill the table or Call 0086 15112554736

en

en es

es