Categories

New Blog

Which Is Better for Your Business Air Cooled Screw Chiller or Water Cooled Chiller

Sep 02, 2025You should pick a chiller that fits your business. Air Cooled Screw Chiller is good for small areas. It does not need much care. Water-cooled units work best in big places. They are more efficient.

Water-cooled chillers have about 60% of the market in 2024. They are used mostly for large businesses.

Air-cooled models are growing quickly because they are easy to set up.

Air cooled screw chillers usually cost less at first. They have a simple design. They do not need cooling towers or extra parts. This makes them cheaper to buy. Here is a table that shows how much air cooled chillers can cost:

|

Chiller Type |

Cost Range |

|---|---|

|

Air-Cooled Chiller |

$5,000 - $50,000+ |

|

Mid-Sized Air-Cooled |

$25,000 - $26,000 total |

|

Water-Cooled Chiller |

Not specified in detail |

Many things change the price of each chiller. You should think about the cooling method, compressor type, and control system. The next table explains these things:

|

Factor |

Description |

|---|---|

|

Cooling method |

Air-cooled chillers are cheaper and easy to put in. Water-cooled chillers need more equipment. |

|

Compressor type |

Screw compressors cost more than scroll compressors for big systems. |

|

Control system |

Better controls make both types cost more. |

Water cooled chillers use less electricity. They work better and save energy. Air cooled chillers use more power, especially when it is hot. If you want to save money every month, water cooled chillers can help. But you also need to pay for water and chemicals for water cooled chillers.

Air cooled chillers are easy to take care of. You just need to clean the coils. You do not need to treat water. Water cooled chillers need more work. You must treat the water and clean the tubes. You also need to check the parts inside. Air cooled chillers are easier to keep up over ten years. Water cooled chillers last longer, sometimes up to 30 years. You might pay more to keep water cooled chillers running, but they can work for a long time.

Tip: If you want less work and lower costs, pick an air cooled screw chiller for your business.

You should think about your local weather before choosing a chiller. Each chiller type works differently in hot or cold places. Air-cooled chillers do not work as well during heatwaves. When it gets hot outside, they must work harder. Their performance goes down. In cold places, air-cooled chillers also lose some efficiency. They do not work as well at part load.

Water-cooled chillers do better in hot weather. They keep working well even when it is very warm. These chillers can run at lower condensing pressures. This helps them stay efficient. In cold places, water-cooled chillers still work well. They often use less energy than air-cooled chillers.

|

Chiller Type |

Performance in Hot Climates |

Performance in Cold Climates |

|---|---|---|

|

Air-Cooled Chillers |

Not as efficient, affected by heatwaves |

Efficiency drops at part load, not as good |

|

Water-Cooled Chillers |

More efficient, steady in high temperatures |

Usually more efficient, works well in cold |

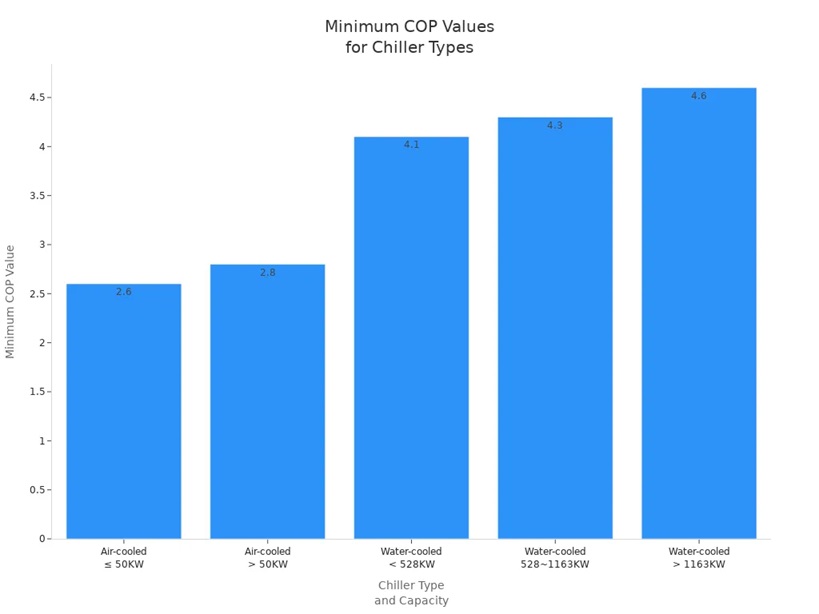

You want your chiller to use less energy. Water-cooled chillers are usually more efficient than air-cooled chillers. The coefficient of performance (COP) shows how well a chiller uses energy. A higher COP means the chiller is more efficient.

|

Chiller Type |

Rated Cooling Capacity |

Minimum COP Value |

|---|---|---|

|

Air-cooled screw chillers |

≤ 50KW |

2.60 |

|

Air-cooled screw chillers |

> 50KW |

2.80 |

|

Water-cooled screw chillers |

< 528KW |

4.10 |

|

Water-cooled screw chillers |

528~1163KW |

4.30 |

|

Water-cooled screw chillers |

> 1163KW |

4.60 |

You can also check the energy efficiency ratio (EER) to compare chillers. Water-cooled chillers have an EER of 3.5. Air-cooled chillers have an EER of 2.8. This means water-cooled chillers save more energy over time.

|

Chiller Type |

Energy Efficiency Ratio (EER) |

|---|---|

|

Air-Cooled Chiller |

2.8 |

|

Water-Cooled Chiller |

3.5 |

|

Screw Chiller |

3.7 |

If you compare air-cooled and water-cooled chillers, you see water-cooled chillers are more efficient. They work better in most climates. Air-cooled chillers are best in cooler places or where water is hard to find.

Think about space before picking a chiller. Air-cooled chillers need more room. They use air to get rid of heat. You must leave open space around them. This helps air move easily. These chillers are often outside. Sometimes, they go on rooftops. Water-cooled chillers use less space inside. But you need extra room for cooling towers. You also need space for pipes.

|

Chiller Type |

Space Requirements |

|---|---|

|

Air-cooled chiller |

Needs more space for airflow and larger condenser units. |

|

Water-cooled chillers |

More compact indoors but require space for cooling towers and pipes. |

Tip: If you do not have much outdoor space, water-cooled chillers can fit inside your building.

Check how hard it is to set up each chiller. Air-cooled chillers are easier to install. You can put them outside. You do not need extra parts. Water-cooled chillers are harder to set up. You must add cooling towers. You need pumps and pipes too. This takes more time and work.

|

Feature |

Air-Cooled Chillers |

Water-Cooled Chillers |

|---|---|---|

|

Installation |

Simpler, often installed outdoors |

More complex, needs cooling tower and extra piping |

Some problems can happen:

Air-cooled chillers are big and heavy. Putting them on a roof can be hard.

Water-cooled chillers need more pipes and cooling towers. This costs more money and time.

If you want a fast and easy setup, pick an air-cooled chiller. If you want better efficiency and have more time, water-cooled chillers may be best.

When you pick a chiller, think about water use. Water-cooled chillers need cooling towers. These towers use a lot of water. Water is lost by evaporation, drift, and blowdown. If you raise the cycles of concentration, you can save water. This can lower water use by up to 20%. Air-cooled chillers do not use water for cooling. They use air instead, so water use is low.

Water-cooled chillers need lots of makeup water each year.

More cycles of concentration in towers help save water.

Air-cooled chillers do not need water for cooling.

Water-cooled chillers can affect the environment a lot. They use much water, which is a problem where water is rare. If you do not treat the water before letting it go, it can hurt plants and animals nearby. These chillers also use power, which can cause more greenhouse gases.

Noise is important when you put in a chiller, especially in cities. Air-cooled chillers make noise from fans, pumps, and compressors. Water-cooled chillers are quieter. Most water-cooled chillers run at 55 to 75 decibels. A well-kept chiller in a medium building might be 60 decibels. This is as quiet as gentle rain.

Air-cooled chillers make noise from fans and moving parts.

Water-cooled chillers are quieter and good for quiet places.

Local rules often limit how loud chillers can be. The World Health Organization says loud noise can harm your health. If your chiller is too loud, you could break city rules. This can upset neighbors and make work less comfortable for workers.

You need to take care of your chiller often. Both air-cooled and water-cooled chillers need regular checks. You should look at refrigerant levels a lot. If you find leaks, fix them fast. Clean the evaporator coils every six months. This helps the chiller work well. Test the electrical parts and change any broken ones. Lubricate moving parts so they last longer. For water-cooled chillers, watch water flow and pressure. Check oil quality and levels to stop breakdowns.

|

Maintenance Task |

Description |

|---|---|

|

Check Refrigerant Levels |

Look at refrigerant levels and add more if needed. Find leaks and fix them quickly. |

|

Inspect and Clean Evaporator Coils |

Clean coils every six months so the chiller works better. |

|

Test Electrical Components |

Check wires and replace any broken parts. |

|

Lubricate Moving Parts |

Make sure moving parts have enough oil. Add more if needed. |

|

Monitor Water Flow and Pressure |

Watch water flow and pressure during checks. |

|

Analyze Oil Quality and Levels |

Test oil for dirt and change it if needed. |

Air-cooled chillers need more care. Water-cooled chillers need less checking, but you must treat water and clean cooling towers. How often you do maintenance depends on how much you use the chiller, its age, and where it is.

You want your chiller to last a long time. Air-cooled chillers work for 15 to 20 years. Water-cooled chillers last 20 to 30 years. Problems happen from dirt, clogs, electrical issues, or not doing maintenance. If you keep up with care, you can stop most problems. Water-cooled chillers need extra water treatment and tower cleaning. Air-cooled chillers need coil cleaning and electrical checks more often.

|

Chiller Type |

Average Lifespan |

|---|---|

|

Air-Cooled Chillers |

15 to 20 years |

|

Water-Cooled Chillers |

20 to 30 years |

Main reasons chillers break:

Dirt buildup

Clogs

Electrical problems

Skipping maintenance

Tip: Doing regular maintenance saves money and keeps your chiller working well.

You want to find the best chiller for your business. The right chiller depends on your building size. It also depends on how much cooling you need and where you are. Each chiller type works best in different places.

If your business is small or you do not have much space, an air cooled screw chiller is a good choice. You can use it in offices or small factories. It is also good if water is hard to get. Air-cooled chillers work well in places with mild weather.

If you run a big place like a hospital or mall, a water cooled chiller is better. Water-cooled chillers give more cooling power. They work well in hot weather and can cool large buildings.

Air-cooled chillers are easy to put in. You can place them outside or on the roof. They do not need extra things like cooling towers.

Water-cooled chillers need more room inside. You need space for cooling towers and pumps. These chillers are quieter and save more energy. But you must plan for water use.

Here is a table to help you pick the right chiller:

|

Decision Factor |

Air-Cooled Chillers |

Water-Cooled Chillers |

|---|---|---|

|

Cooling Capacity |

Good for small and medium cooling needs |

Best for big cooling needs and large buildings |

|

Space Requirements |

Small, fits tight spaces |

Needs room for cooling towers and pumps |

|

Initial Investment |

Costs less at first, fewer parts |

Costs more, needs extra equipment |

|

Energy Efficiency |

Not as good in hot weather, costs more to run |

More efficient, works well in most weather |

|

Environmental Impact |

Uses more energy, bigger carbon footprint |

Uses more water, smaller carbon footprint |

|

Noise Level |

Louder because of fans |

Quieter, most noise is outside |

Tip: If you want something simple and easy to set up, pick an air cooled chiller. If you need strong cooling for a big building, a water cooled chiller is better.

Use this checklist to help you choose the best chiller. Answer each question to see which chiller fits your needs.

|

Factor |

Description |

|---|---|

|

Cooling Capacity |

Do you need cooling for a small or big area? |

|

Energy Efficiency |

Do you want to save money on energy bills? |

|

Special Features |

Does your business need smart controls or special options? |

|

Smart Controls |

Will real-time monitoring help your team? |

|

Future Growth Consideration |

Do you plan to grow and need a system that can expand? |

If you picked "small area" and "easy setup," an air-cooled chiller is best for you.

If you need lots of cooling, want to save energy, and plan to grow, a water-cooled chiller is better.

Note: Always think about your local weather, water supply, and future plans before you choose.

Now you can match your needs with what each chiller offers. This helps you pick the best chiller and avoid spending too much. The right chiller keeps your business working well and saves money over time.

You can look at the table to see the main differences. Air-cooled chillers use air to cool things. They fit in smaller spaces. Water-cooled chillers use water for cooling. They work better in big buildings. Use the checklist to find what you need. For the best choice, ask an HVAC expert before you pick a chiller.

|

Feature |

Air-Cooled Chillers |

Water-Cooled Chillers |

|---|---|---|

|

Cooling Mechanism |

Uses air |

Uses water |

|

Lifespan |

15 – 20 years |

20 – 30 years |

|

Efficiency |

Depends on air temperature |

More efficient |