Categories

New Blog

2025 Guide to Water Cooled Screw Chiller vs Air Cooled Chiller for Industry

Sep 11, 20252025 Guide to Water Cooled Screw Chiller vs Air Cooled Chiller for Industry

If you want the most efficient cooling for large-scale industrial operations in 2025, you should consider a Water Cooled Screw Chiller. This chiller type remains the preferred choice for high thermal output needs, holding 59.5% market share in 2024. You need to weigh key factors such as cost, energy efficiency, installation space, maintenance, environmental impact, water use, noise, and suitability for your industry and location.

|

Factor |

Water-Cooled Chillers |

Air-Cooled Chillers |

|---|---|---|

|

Cooling Capacity |

More suitable for larger cooling needs |

Better for smaller to medium applications |

|

Installation Space |

Requires indoor placement with cooling towers |

Can be installed outdoors, saving indoor space |

Choosing the right chiller for your facility depends on several important factors. You want to compare water cooled screw chillers and air-cooled chillers side by side to see which fits your needs best. Below, you will find a summary table that highlights the main differences. This table helps you quickly scan the features that matter most for industrial cooling in 2025.

|

Factor |

Water Cooled Screw Chiller |

Air-Cooled Chiller |

|---|---|---|

|

Initial Cost |

Higher due to cooling tower and piping |

Lower, simple installation |

|

Energy Efficiency |

High, especially in large-scale operations |

Moderate, best for small to medium setups |

|

Installation |

Needs indoor space and water supply |

Outdoor installation, saves indoor space |

|

Maintenance |

Regular water treatment and tower upkeep |

Simpler, less frequent maintenance |

|

Environmental Impact |

Uses water, but supports eco-friendly refrigerants |

No water use, may have higher energy demand |

|

Water Use |

Requires reliable water source |

No water needed |

|

Noise |

Operates quietly indoors |

Fans can create more noise outdoors |

|

Lifespan |

Long, with proper maintenance |

Moderate, depends on environment |

|

Suitability |

Best for large, high-temperature industries |

Ideal for smaller, space-limited sites |

You should also consider operational characteristics. Water cooled screw chillers perform well in high-temperature environments and offer precise cooling. Air-cooled chillers work best where water is scarce or installation space is limited. Your final choice depends on your cooling capacity requirements and the environmental conditions at your site.

You will find that a water cooled screw chiller uses water as the main medium to remove heat from your process. The system pumps water through a sealed condenser, where it absorbs heat from the refrigerant. This heated water then travels to a cooling tower, where it releases the heat into the atmosphere. The cooled water returns to the chiller, and the cycle repeats.

Modern water cooled screw chillers often include advanced features that enhance performance and efficiency. For example, a double compressor system allows the chiller to handle larger loads with greater stability. You can benefit from a PLC control system, which provides smart monitoring and easy adjustments through a touchscreen interface. These controls let you track system diagnostics, log historical data, and even access the chiller remotely. Many models use eco-friendly refrigerants, which help reduce environmental impact while maintaining high efficiency.

Air-Cooled Chiller Operation

An air-cooled chiller works differently. Instead of using water, it relies on fans to blow air across exposed condenser tubes. The refrigerant inside these tubes releases heat, which the moving air carries away. This process makes air-cooled chillers easier to install, since you do not need a cooling tower or extra piping.

You can place an air-cooled chiller outdoors, such as on a rooftop or beside your facility. This setup saves indoor space and reduces installation complexity. However, air is less effective than water at absorbing heat, so air-cooled chillers may not match the efficiency or performance of water cooled screw chillers for large industrial loads.

|

Feature |

Water-Cooled Chillers |

Air-Cooled Chillers |

|---|---|---|

|

Efficiency |

More efficient for large loads due to water's heat capacity |

Less efficient, relies on air which is less effective |

|

Space Requirements |

Requires mechanical rooms and cooling towers |

Requires less space, can be placed on rooftops |

|

Maintenance Needs |

Higher maintenance due to more equipment |

Lower maintenance due to simpler design |

|

Service Life |

Generally longer due to indoor placement |

Shorter due to exposure to environmental elements |

You gain several benefits when you choose a water cooled screw chiller for your industrial facility.

You achieve high energy efficiency, especially in large-scale operations. Many water cooled screw chillers reach COP values up to 4.98 and IPLV ratings as high as 6.67.

You control temperature with precision. Stepless capacity modulation lets you adjust cooling from 0 to 100%, so you match your process needs exactly.

You enjoy advanced safety features. Modern water cooled screw chillers include multiple protection devices, such as over-temperature and pressure safeguards.

You benefit from reliable performance in demanding environments. These chillers handle capacity ranges from 50 to over 1,000 tons, making them ideal for industries like plastic manufacturing and concrete mixing.

You extend the lifespan of your equipment. Indoor placement shields the chiller from weather, which helps maintain efficiency and reduces long-term costs.

You should consider some challenges before installing a water cooled chiller.

You face installation complexity. Proper planning and execution are crucial for setting up a water-cooled chiller. You need to follow a step-by-step guide to ensure efficient operation and system longevity.

You must manage water requirements. Untreated water can cause higher condenser pressures and lower heat transfer efficiency. You need chemical treatments to keep the system running smoothly.

You take on regular chiller maintenance tasks. Tube cleaning is essential for optimal heat transfer. You also need to analyze and change compressor oil. Maintaining flow rates between 3 to 12 feet per second helps prevent operational issues.

You invest more upfront. The initial cost is higher due to the need for cooling towers and extra piping, but you may save on operating costs over time.

Water-cooled chillers suit large facilities with reliable water sources and skilled maintenance teams. If you want top chiller efficiency and precise control, this type of chiller meets your needs.

You will find that air-cooled chillers offer several practical benefits for industrial settings. These systems stand out for their straightforward installation process. You do not need to set up cooling towers or complex plumbing, which helps you save both time and money. Many facilities choose air-cooled chillers because they can be placed outdoors, freeing up valuable indoor space for other equipment or operations.

Maintenance tasks are also simpler. You avoid the need for water treatment systems and the frequent upkeep required by cooling towers. This means you spend less time and resources on regular maintenance.

Here is a quick overview of the most commonly cited advantages:

|

Advantage |

Description |

|---|---|

|

Lower Installation Costs |

No need for cooling towers or extra plumbing, making installation more affordable. |

|

Simplified Maintenance |

Fewer components mean easier and less frequent maintenance. |

|

Smaller Footprint Indoors |

Outdoor installation frees up indoor space for other uses. |

|

No Water Consumption |

Perfect for areas with water restrictions or high water costs. |

You should also consider some limitations before choosing an air cooled chiller. These systems often have lower energy efficiency compared to water-cooled models, especially when you need to cool large industrial loads. Air, as a cooling medium, cannot absorb as much heat as water, so the system may use more electricity to achieve the same cooling effect.

Noise can be another concern. Air-cooled chillers use large fans to move air across the condenser coils. These fans can generate noticeable noise, especially when the chiller operates at full capacity. If your facility is located near offices or residential areas, you may need to plan for noise reduction measures.

Key Comparison Factors

You need to consider both initial and ongoing costs when choosing a chiller. Water cooled screw chillers usually require a higher upfront investment. You pay for the chiller itself, a cooling tower, and extra piping. Installation takes longer because you must set up a continual water source and allocate space for additional equipment. Air-cooled chillers cost less to install. You can place them outdoors and avoid the expense of a cooling tower. Over time, water cooled screw chillers may save you money through lower energy bills, especially in large facilities. Air-cooled chillers often have higher operating costs in hot climates due to lower efficiency.

You want your chiller to deliver strong performance while using less energy. Water cooled screw chillers excel in energy efficiency. Water absorbs heat better than air, so these chillers use less electricity to cool large loads. Advanced models feature eco-friendly refrigerants and PLC controls that optimize operation. Air-cooled chillers work well for small to medium applications but may consume more energy in high-temperature environments. If you run a large industrial process, you benefit from the superior efficiency of water cooled screw chillers.

You must plan for installation requirements before making a decision. Water cooled screw chillers need indoor space and a reliable water supply. You also install a cooling tower, which adds complexity and time to the project. Air-cooled chillers are stand-alone units. You can install them quickly outdoors, saving valuable indoor space. If you want a faster setup, air-cooled chillers offer a clear advantage.

Maintenance

You should prepare for regular maintenance to keep your chiller running smoothly. Water cooled screw chillers require more attention. You need to treat water to prevent corrosion and clogs. You also clean tubes and monitor water quality. Air-cooled chillers have fewer components, so maintenance is simpler. You mainly check refrigerant levels and clean condenser coils.

|

Issue |

Description |

Solutions |

|---|---|---|

|

Low Refrigerant Levels |

Ice may form if refrigerant levels drop too low. |

Regularly check and top up refrigerant levels. |

|

Water Flow Issues |

Inadequate water flow can lead to ice buildup. |

Ensure proper maintenance and check for blockages. |

|

Malfunctioning Sensors |

Faulty temperature sensors can prevent proper operation. |

Replace faulty sensors to avoid ice buildup. |

|

Water Quality Issues |

Hard water and contaminants can damage components and reduce efficiency. |

Implement a water treatment system and regularly monitor water quality. |

|

Improper Operation |

Operating outside recommended parameters can cause wear and failure. |

Avoid overloading and ensure settings align with manufacturer recommendations. |

|

Power Fluctuations |

Voltage spikes can harm electrical components. |

Use voltage regulators and conduct regular inspections of electrical systems. |

Corrosion can lead to leaks and damage if you do not treat water properly.

Poor maintenance may result in clogs and reduced efficiency.

You want your chiller to last as long as possible. Water cooled screw chillers often have a longer lifespan. Indoor placement protects them from weather and temperature swings. You extend their life with regular maintenance and water treatment. Air-cooled chillers sit outdoors, so they face rain, dust, and heat. These conditions can shorten their service life. If you prioritize durability, water cooled screw chillers offer better long-term value.

You need to think about how your choice affects the environment. Water cooled screw chillers use water, but many modern models run on eco-friendly refrigerants. Advanced controls help reduce energy use and emissions. Air-cooled chillers do not consume water, which makes them suitable for regions with water scarcity. However, they may use more electricity, especially in hot climates, which can increase your carbon footprint.

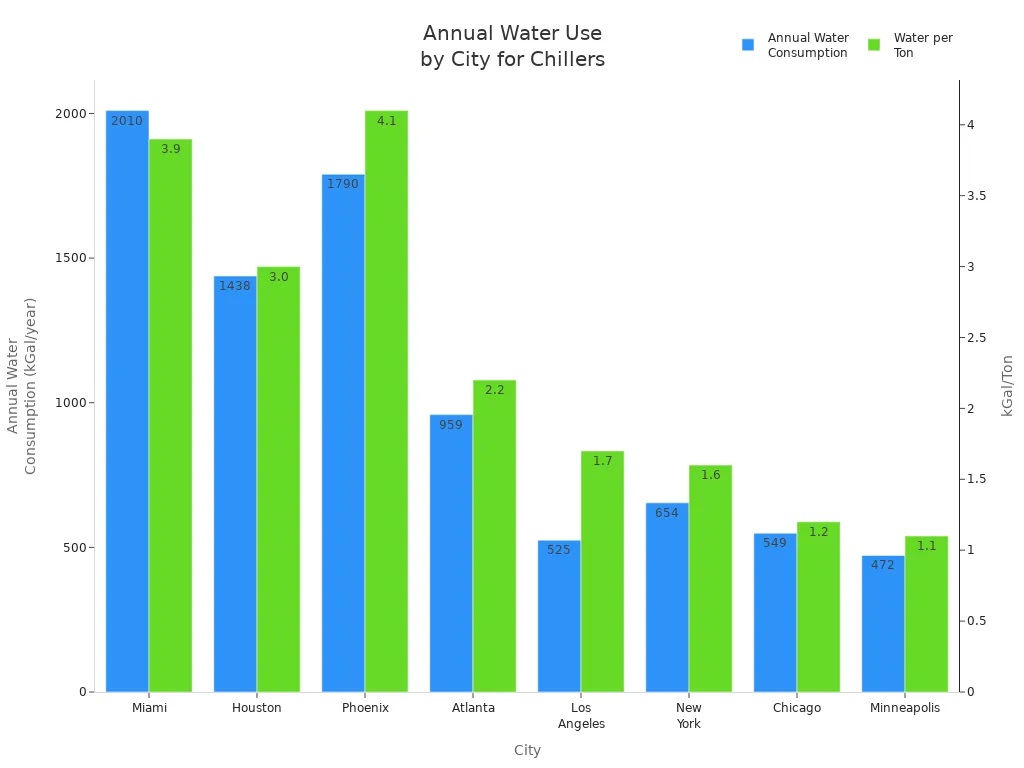

You must evaluate water consumption before selecting a chiller. Water cooled screw chillers require a steady supply of water. Usage varies by city and climate. For example, annual water consumption per ton ranges from 1.1 kGal in Minneapolis to 4.1 kGal in Phoenix.

Air-cooled chillers do not use water, making them ideal for facilities in water-restricted areas.

You should consider noise levels, especially if your facility is near offices or residential zones. Water cooled screw chillers operate quietly indoors, with noise levels between 55 and 65 decibels. This is similar to a conversation or background music. Air-cooled chillers produce more noise, ranging from 70 to 80 decibels, which you can compare to a vacuum cleaner or a busy street.

|

Chiller Type |

Noise Level (dB) |

Description |

|---|---|---|

|

Air-Cooled Chillers |

70 to 80 |

Comparable to a vacuum cleaner or busy street |

|

Water-Cooled Chillers |

55 to 65 |

Similar to a conversation or background music |

Suitability by Industry

Large-Scale Manufacturing

You should choose a water cooled screw chiller for large-scale manufacturing. Industries such as plastics, chemicals, and concrete production rely on these chillers for their broad capacity coverage and reliable load-following performance. Market reports show screw chillers hold a 38.3% share in these sectors, with centrifugal chillers gaining momentum due to efficiency and reduced maintenance needs.

|

Chiller Type |

Market Share |

Key Features |

|---|---|---|

|

Screw Chillers |

38.3% |

Broad capacity, reliable operation |

|

Centrifugal Chillers |

Gaining |

High efficiency, low maintenance |

Screw chillers offer cost-effectiveness and low maintenance.

You see them most often in plastics, chemicals, and pharmaceuticals.

For medium and small facilities, you need to focus on operational efficiency and cost-effectiveness. Chillers with capacities between 50 and 200 tons fit these operations well. You should consider the layout and available space in your facility, as well as the need for precise temperature control.

|

Factor |

Description |

|---|---|

|

Cooling Capacity |

50-200 tons commonly used |

|

Energy Efficiency |

Critical for selection |

|

Installation Environment |

Facility layout and space influence suitability |

|

Application Requirements |

Food & beverage, pharmaceuticals, chemicals drive demand |

You benefit from chillers that maintain precise temperature and offer easy installation.

If your facility is in a water-restricted area, you should select an air-cooled chiller. These chillers do not require a water supply or cooling tower, making them ideal for remote sites or regions with limited water resources.

|

When to Use Air-Cooled Chillers |

Why It Makes Sense |

|---|---|

|

Remote or water-scarce locations |

No need for water supply or cooling towers |

|

Projects needing fast deployment |

Easier to install, no water piping required |

|

Tight budgets |

Lower initial investment |

|

Urban environments with space limits |

Rooftop-ready, compact size |

Air-cooled chillers help you avoid water costs and simplify installation.

In high temperature industrial areas, you should rely on water cooled screw chillers. Water has higher thermal conductivity than air, so these chillers deliver greater cooling efficiency and stable performance. You also experience quieter operation because they do not depend on large fans.

|

Feature |

Water-Cooled Chillers |

Air-Cooled Chillers |

|---|---|---|

|

Cooling Efficiency |

Greater |

Less efficient in hot climates |

|

Noise Level |

Quieter |

Noisier due to fan operation |

|

Performance in Hot Climates |

Consistent and stable |

Struggles with efficiency |

You need to consider site conditions when choosing a chiller. In urban environments with limited space, air-cooled chillers fit well on rooftops and offer a compact footprint. For remote sites or projects needing fast deployment, air-cooled chillers provide easy installation and lower initial costs. Water-cooled chillers consistently outperform air-cooled systems in environments demanding high efficiency and stable operation, such as large-scale manufacturing or a data center.

Choose air-cooled chillers for space-limited urban sites or remote locations.

Select water-cooled chillers for high-capacity, efficiency-driven projects.

You will see major advances in energy-saving technology for water cooled screw chillers in 2025. Manufacturers now use variable speed drives and compressors, which let your chiller adjust its output based on cooling demand. This feature helps you achieve greater energy efficiency and higher efficiency during peak and off-peak hours. Advanced heat exchanger designs improve heat transfer, so your water cooled chiller uses less energy. Many systems now include closed-loop cooling and hybrid cooling, which combine wet and dry methods to reduce water use. You can also benefit from free cooling and heat recovery, which capture waste heat for other applications.

|

Feature |

Description |

|---|---|

|

Variable Speed Drives |

Adjust operation for optimal energy use |

|

Advanced Heat Exchangers |

Boost heat transfer, lower energy needs |

|

Hybrid Cooling |

Mixes wet and dry cooling to save water |

|

Free Cooling |

Uses ambient air to reduce compressor energy |

|

Heat Recovery |

Captures waste heat for heating |

You can now control your water-cooled chiller with smart technology. PLC controllers and microprocessor systems monitor every function and keep your chiller running smoothly. Touch screen interfaces make operation simple and give you detailed alarm information for troubleshooting. Intelligent control systems allow remote monitoring, so you can track performance from anywhere. Automation features help you maintain precise temperature control, which is vital for data center cooling and other sensitive environments.

|

Feature |

Description |

|---|---|

|

PLC Controller |

Delivers temperature accuracy within ±0.5 degrees |

|

Touch Screen Interface |

Offers intuitive operation and alarm details |

|

Remote Monitoring |

Enables real-time performance tracking |

|

Predictive Maintenance |

Uses AI to prevent failures and optimize efficiency |

You will notice a strong shift toward eco-friendly refrigerants in water-cooled chillers. Companies now use refrigerants with lower global warming potential to meet new regulations and sustainability goals. These refrigerants support green building standards and help you lower your carbon footprint. Manufacturers also focus on sustainable materials and processes, so your chiller meets environmental requirements. The rise of adaptable, cost-effective cooling solutions means you can choose a water cooled screw chiller that fits your needs and supports environmental responsibility.

Lower GWP refrigerants reduce environmental impact.

Sustainable manufacturing supports green building trends.

Hybrid chillers offer flexible, efficient cooling.

You must stay informed about new regulations affecting water-cooled chillers. In 2025, stricter standards require you to use chillers that meet ASHRAE and LEED guidelines. These rules encourage the use of eco-friendly refrigerants and energy-saving technologies. You need to ensure your chiller complies with local and international standards to avoid penalties and support sustainability. Manufacturers now design chillers with advanced safety protections, including over-temperature and pressure safeguards, to meet these requirements.

OUMAL Chiller is a cooling tower and chiller system manufacturer integrating R&D,manufacturing and customization.Provide professional solutions.15+ years of work experience!