Categories

New Blog

Which Is Better for Your Facility Water Cooled Screw Chiller or Air Cooled Chiller

Jul 03, 2025

You usually pick a water cooled screw chiller for big places or places that need to be quiet. Air cooled chillers are good for smaller places, places with little space, or where there is not much water.

|

Factor |

Water Cooled Screw Chiller |

Air Cooled Chiller |

|---|---|---|

|

Efficiency |

High |

Moderate |

|

Cost |

Higher |

Lower |

|

Maintenance |

More |

Less |

|

Climate Suitability |

Any climate |

Mild climates |

|

Space |

Needs mechanical room |

Needs outdoor space |

|

Noise |

Quiet |

Louder |

|

Lifespan |

Long |

Shorter |

Every place is different. Think about your space, money, and weather before you choose.

Water cooled screw chillers use less energy. They are quieter and last longer. These chillers work well in big buildings. They are good for places that are very hot.

Air cooled chillers cost less at first. They do not need much care. They fit in small spaces. They are good where there is not much water. But they are louder. They do not work as well in hot weather.

Pick your chiller by looking at your building size. Think about the weather and how much water you have. Also, check your budget. This helps you get the best cooling and save money.

A water cooled screw chiller gives strong cooling for big places. It takes heat from your building and puts it into water. The water goes through pipes to a cooling tower. The cooling tower lets the heat out into the air. You find these chillers in hospitals, factories, and big offices. They are good for places that need a lot of cooling. Groups like ASHRAE 90.1 and ARI say these chillers work well for big jobs and save energy. New models use special drives and better refrigerants. This helps save more energy and follow strict rules.

An air cooled chiller is good if you want something simple. It uses fans to blow air over coils to cool the refrigerant. The heat goes straight into the outside air. You do not need a cooling tower or extra water. These chillers are good for small buildings or places with little water. They are easier to put in and take care of. But they might use more energy, especially when it is hot outside.

Here is a quick look at how they work:

|

Metric / Parameter |

Water Cooled (Underground Heat Exchanger) |

Air Cooled / Conventional Systems |

|---|---|---|

|

Energy Consumption Reduction |

14% less than water-cooled with cooling tower |

Baseline (uses more energy) |

|

Water Consumption |

No water used (0 m³/m²/day) |

About 1.95 m³/m²/day water used |

|

COP Increase |

6% to 18% higher in ground source heat pump systems |

Baseline COP |

|

Heat Transfer Enhancement |

Up to 1.5 times better |

Baseline heat transfer |

A water cooled screw chiller gives better efficiency and heat transfer. Air cooled chillers are easier to set up and cost less at first. But they may not work as well in big or busy places.

You want to use less energy and save money. Water cooled screw chillers are usually more efficient. They use water to move heat, which works better than air. Studies show that if you run chillers together in a smart way, you can cool up to 93 kW more each hour. This saves a lot of energy over time. In big buildings, smart controls help cut energy use by over 11%. They also make the Coefficient of Performance (COP) go up by more than 21%. This means your system does more work for each unit of electricity. Air cooled chillers can save energy too if they have variable-speed fans and smart controls. But they are not as efficient as water cooled chillers, especially when it is hot outside.

You need to think about both the starting cost and the cost to keep it running. Water cooled screw chillers cost more to put in. You need a cooling tower, pumps, and extra pipes. The base cost is about $1,000 for each ton of cooling. Air cooled chillers cost less to install because they do not need extra water systems. But they may use more electricity, especially in hot or dry places. Here is a quick look at cost factors:

|

Parameter |

Water Cooled Screw Chiller |

Air Cooled Chiller |

|---|---|---|

|

Installation Cost |

Higher (cooling tower, piping) |

Lower (no cooling tower needed) |

|

Operating Cost |

Lower (better efficiency) |

Higher (less efficient in heat) |

|

Water Use |

High |

None |

|

Maintenance Cost |

Higher (more parts to service) |

Lower (simpler system) |

You want a system that is easy to take care of. Water cooled screw chillers need more work. You have to check the cooling tower and clean the pipes. You also need to watch for scale or rust. These systems have more moving parts. Air cooled chillers are simpler. You just clean the coils and check the fans. This means less downtime and fewer repairs. If you want less work, air cooled chillers are easier to handle.

If your building needs a lot of cooling, water cooled screw chillers are better. They can handle big loads and work well in hospitals, factories, or tall office buildings. They can run for long hours without losing power. Air cooled chillers are good for smaller buildings or places that do not need as much cooling. They may not work as well if you try to cool a big space or run them all day.

The weather where you live matters. Water cooled screw chillers work well in any climate, even if it is hot or humid. They do not lose much efficiency when it gets hot outside. Air cooled chillers work best in places that are not too hot. When it is hot, they use more electricity and do not cool as well. Studies show that in Mediterranean climates, smart fan controls can save up to 12% on electricity. In subtropical areas, advanced controls help air cooled chillers save energy. But water cooled chillers still work better in high heat.

|

Chiller Type |

Best Climate |

Key Performance Notes |

|---|---|---|

|

Water cooled screw chiller |

Any (hot, humid, dry) |

Keeps high efficiency in all conditions |

|

Air cooled chiller |

Mild, not too hot |

Efficiency drops in high heat; best with smart controls |

You need to plan where to put your chiller. Water cooled screw chillers need a mechanical room and space for a cooling tower. They run quietly, which is good for hospitals or offices where noise matters. Air cooled chillers go outside. They need open space and make more noise because of their fans and compressors. If you do not have much indoor space or do not mind noise, air cooled chillers may work for you.

You want your chiller to last a long time. Water cooled screw chillers usually last longer—often 20 to 30 years—if you take care of them. Their parts wear out slowly because they run in steady conditions. Air cooled chillers last about 15 to 20 years. Weather and temperature changes can make them wear out faster.

If you want a quiet, long-lasting, and efficient system for a big building, water cooled screw chillers are often best. For smaller spaces or places with little water, air cooled chillers are simpler and cost less.

A water cooled screw chiller gives strong cooling. It works well for big buildings or places needing steady cooling. This system saves energy, so you pay less over time. These chillers are quiet, so they fit in hospitals, hotels, or offices where noise is a problem. If you take care of it, it will last longer.

Tip: You must have a mechanical room and a cooling tower. Make sure you have enough space and water for this system.

Pros:

High energy efficiency

Quiet operation

Handles large cooling loads

Long lifespan

Cons:

Higher installation cost

Needs regular maintenance

Requires water and extra space

Pick an air cooled chiller if you want something simple. This system does not need a cooling tower or much indoor space. You can put it outside, so you save room inside. You spend less money to install and take care of it. This chiller is best for small buildings or places with little water.

Note: Air cooled chillers can be loud. They may not cool well when it is very hot.

Pros:

Lower upfront cost

Simple installation

Less maintenance

No water needed

Cons:

Louder operation

Lower energy efficiency

Shorter lifespan

Not ideal for large cooling needs

You need to pick a chiller that fits your building. Big buildings, like data centers or factories, need more cooling. Small offices or stores do not need as much. You can use cooling load numbers to help you choose:

|

Facility Type |

Cooling Load Benchmark (ft² per refrigeration tonne) |

|---|---|

|

Data Rooms |

80 - 100 |

|

Clean Rooms |

100 - 300 |

If your building is large or needs lots of cooling, think about a water cooled screw chiller. These chillers work well for big jobs and save energy when running hard. For small spaces, an air cooled chiller is usually better and cheaper to run.

Tip: Chillers work best at 40-60% of their top power. If your chiller is too big or too small, you waste energy and money.

Where you live and how much water you have matter a lot. Hot weather makes chillers work harder. Humid air means you need more cooling. If you live where it is hot or humid, a water cooled screw chiller keeps working well. In dry places or where water is hard to get, air cooled chillers or adiabatic cooling systems use up to 90% less water than old cooling towers.

Ambient temperature: Hotter weather uses more energy.

Relative humidity: More humidity means you need more cooling.

Water availability: If water is low, air cooled chillers are better.

Smart technology, like IoT monitoring, helps you watch water, temperature, and energy use. This makes it easier to change your system for the best results.

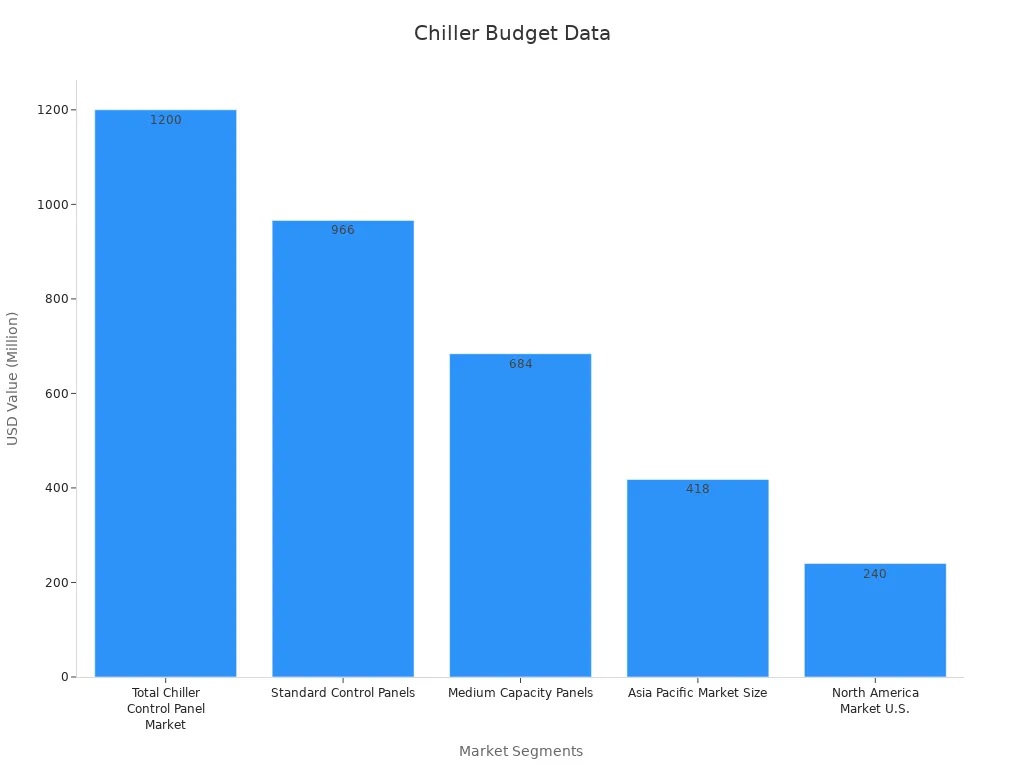

You need to think about your money and your cooling needs. The cost to buy, run, and fix your chiller all matter. Here is a quick look at new market numbers:

|

Aspect |

2023 Value (USD) |

Projected 2032 Value (USD) |

CAGR / Notes |

|---|---|---|---|

|

Total Chiller Control Panel Market |

1.2 billion |

Growing at 5% CAGR |

Demand for energy-efficient HVAC |

|

Standard Control Panels |

966 million |

1.5 billion |

Affordable and functional |

|

Medium Capacity Panels (50-300 tons) |

684 million |

Over 1 billion |

Good for many facility sizes |

|

Energy Savings from AI Systems |

N/A |

Up to 30% reduction |

AI-powered controls cut energy use |

Newer chillers with AI controls can use up to 30% less energy. Cloud monitoring helps you save money by making your chiller work better and break down less. If you do not have much money, an air cooled chiller costs less to buy and fix. If you want to save money in the long run, a water cooled screw chiller with smart controls can lower your bills over time.

Pick a water cooled screw chiller if your building is big and needs lots of cooling. Air cooled chillers are better for small places. Think about what your building needs and look at the features. Talk to an HVAC expert for help. This way, you can choose the best chiller for good, steady cooling.

You should check your chiller every month. Clean coils, check water quality, and inspect moving parts to keep your system running well.

You can use an air cooled chiller for a large building, but it may not cool as efficiently as a water cooled system.

Water cooled chillers work better for high-demand spaces.