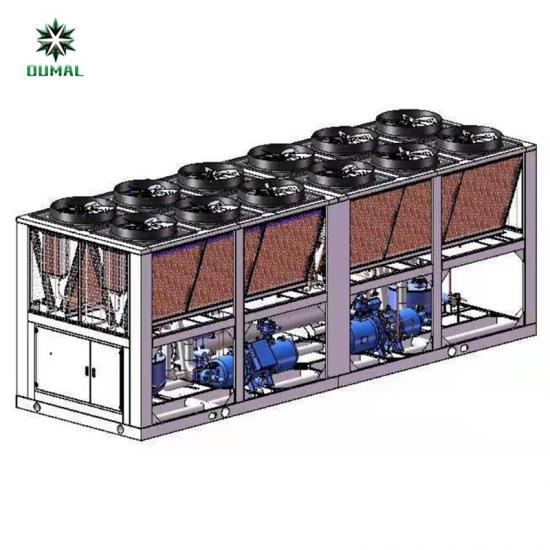

100 tr industrial air cooled chiller

A 100tr air cooled chiller is a cooling water system that uses screw compressors and air cooling method to provide cooling capacity 350kw. It is commonly used in industrial applications where large cooling loads are required, such as in commercial buildings, manufacturing facilities, data centers, and process cooling applications.

100tr Air cooled chiller for Industrial production: used in industries such as mechanical manufacturing, metal processing, plastic processing, etc., to cool machine tools and processing equipment, ensuring the normal operation of equipment and product quality.

100 tr air cooled chiller for Electronics industry: used in semiconductor and electronic component manufacturing to cool production equipment, ensure a constant temperature in the production environment, and ensure the stability and reliability of electronic products.

100 tr air cooled chiller for Food processing: used to cool food processing equipment, maintain food freshness and quality, and extend shelf life.

Air cooled chiller for Medical and Health: Used in pharmaceutical production and laboratories to cool drug production equipment, ensuring drug quality and safety.

Air Cooled Chiller for Air conditioning system: In large public buildings, shopping malls, hotels and other places, as part of the central air conditioning system, it provides stable cooling effect.

Chiller for Chemical industry: used for cooling equipment such as reaction vessels and cooling towers to ensure smooth chemical reactions.

Water Chiller for Printing industry: used to cool printing machines, prevent paper deformation, and affect printing quality.

Industrial Chiller for Textile industry: used for cooling textile equipment to ensure product quality and efficiency.

Air Cooled Chiller for Plastic industry: used for cooling molds, improving product accuracy and surface quality.

Chiller for Energy industry: used to cool equipment during energy production, conversion, and storage processes, improving energy utilization efficiency.

In addition, it is widely used in industries such as medical, biological, laser, metallurgy, equipment manufacturing, electroplating, and plastic processing.

The main features of a 100 tr air cooled chiller include:

Cooling capacity: The chiller is designed to provide a cooling capacity of 100 tons, which is equivalent to 1,200,000 BTU/h or 351.6 kW of cooling power.

Screw compressor: The chiller is equipped with a screw compressor, which is known for its high efficiency, reliability, and smooth operation. The screw compressor is designed to handle large cooling loads and maintain consistent cooling performance. Oumal Screw Chiller use High Quality Hanbell screw compressor, Bitzer Screw Compressor, and other brands if you need.

Air-cooled condenser: Unlike water-cooled chillers that rely on water for heat dissipation, air-cooled chillers use ambient air for cooling the refrigerant. The chiller is equipped with an air-cooled condenser that transfers heat from the refrigerant to the surrounding air. The 100 tr air cooled chiller use Air cooled high-efficient inner threaded copper-tubing aluminum fin type with Low noise outer rotor fans.

Efficient heat exchanger: The chiller incorporates a high-efficiency heat exchanger that maximizes heat transfer between the refrigerant and the cooling medium (air or water). This helps to optimize the cooling process and improve energy efficiency. The 100tr air cooled screw chiller usually equipped with Shell and Tube Evaporator.

Integrated controls: The chiller is typically equipped with advanced control systems that allow for precise temperature and pressure regulation, as well as protection mechanisms to ensure safe and reliable operation. The Air cooled Screw Chiller control system is Siemens PLC with HMI. Intelligent temperature control, easy to operate.

Compact design: Air-cooled chillers are often designed to be compact and space-saving, making them suitable for installations where space is limited.

Easy installation and maintenance: The chiller is designed for ease of installation and maintenance. It may come with features such as removable panels, accessible components, and user-friendly interfaces to simplify operation and service.

Overall, a 100 tr air-cooled screw chiller provides efficient and reliable cooling for medium to large-scale applications, offering a balance between performance, cost-effectiveness, and ease of installation and maintenance.

Our 100TR air cooled chiller is specifically designed to meet the cooling demands of the plastic processing industry. 100 ton air cooled screw water chiller offers efficient and reliable cooling solutions that ensure process stability and enhance product quality. Featuring advanced refrigeration technology and durable construction, this 100 ton air cooled screw water chiller is ideal for a wide range of plastic processing applications.

Details of the 100 Ton Air Cooled Screw Water Chiller

100 Ton Air Cooled Screw Water Chiller Product Specification

| Item Model | OMC-120ADH | ||

| Cooling Capacity | kcal/h | 302376 | |

| KW | 351.6 | ||

| Ton | 100.0 | ||

| Btu/h | 1200000 | ||

| Input Power | KW | 112.6 | |

| Max.running current | A | 264 | |

| Power | 3PH-380V/415V 50Hz (3PH-220V/440V 60Hz ) | ||

| Refrigerant | Type | R22 ( R407C ) | |

| Charge quantity | kg | 84 | |

| Control Mode | Expansion Valve | ||

| Compressor | Type | Semi-Hermetic Screw | |

| Power | KW | 51.9 x 2 | |

| Start-up Mode | Y-△ | ||

| Capacity control | % |

0-25-50-75-100 (0-33-66-100) |

|

| Evaporator | Type | Shell and Tube | |

| Chilled water flow | m3/h | 60.5 | |

| Pipe Diameter | lnch | 3" | |

| Condenser | Type | Air cooled high-efficient inner threaded copper-tubing aluminum fin type | |

| Fan | Type | Low noise outer rotor | |

| Power | KW | 8.8 | |

| cooling air flow | m3/h | 120000 | |

| Dimension | Length | mm | 4800 |

| Width | mm | 1950 | |

| Height | mm | 2200 | |

| Net Weight | kg | 3250 | |

| Running Weight | kg | 3460 | |

| safety protection: compressor over heat protection, over load protection,high and low pressure protection,reversed and lacking phase protection, anti-freezing protection, flow switch | |||

FAQ

Q1: What's the Compressor Brand of your Air Cooled Screw Chiller ?

A1: Regarding the Screw Chiller, We use Hanbell screw compressor mostly, We also use Bitzer Brand if you need. If you are sensitive for the Chiller Price, we can also use Refcomp or other Brands.

Q2: Which Refrigerant type are available for your Air Cooled Screw Chiller?

A2: According to environmental requirements, we provide refrigerant type R407C,R404A,R507A, R134A, R513A or R1234yf for the Air Cooled Screw Chiller. If R22 allowed we can also provide.

Q3: Can you customized the chillers according to our local voltage and frequency and other different requirements?

A3: Each air-cooled chiller is customized according to the voltage and frequency required by the customer to ensure that the chiller meets the working conditions. Therefore, after receiving the inquiry for the chiller, we will always confirm the voltage and frequency with the customer. And we also customized the chiller according to client's different needs.

Q4: What's the warranty?

A4: We offer 15 months warranty for free if confirmed by both side damage in the quality reason.

en

en es

es