12 KW Mold temperature controller Unit for injection molding

Mold temperature controller including water type molde tempereature controller and oil type temperature controller.Mold temperature controller or Injection molding temperature controllers or temperature control units, are commonly used in the plastic injection molding industry. Injection molding is a manufacturing process in which parts or products are produced by injecting various plastic materials into molds. Pelletized, raw plastic material is fed through a hopper into a heated barrel with a reciprocating screw. Molds can be of a single cavity or multiple cavities. Depending on the size of the cavities and the dimension of the mold, more than one temperature control unit may be needed for precise temperature control.

The melted material is forced into the preheated mold where the material solidifies. Temperature control units are used to preheat the mold and then to keep the mold at the temperature set point by circulating coolant (water or oil) through the mold.

The coolant absorbs heat from the mold (which has absorbed heat from the hot pastic) and keeps the mold at proper temperature to solidify the plastic.

OUMAL precise temperature control units are instrumental for improved parts, quality,and high cycle times.

Mold temperature controller Quick Details

| ●: | P.I.D. temperature control, high accurace, high efficiency and energy saving |

| ●: | Water / Oil type, Heating temperature up to 180℃ / 350℃ |

| ●: | Build in High temperature pump |

| ●: | Schneider electrical components, Brand Soleniod valve |

| ●: | Stainless steel pipe, anti-corrosion, anti-leakage, long life service |

| ●: | Delicate appearance, space saving, simple and intuitive operation,easy maintains |

| ●: | Different Temperature can be customized |

Mold temperature controller Application:

Mold temperature controllers are widely used in various industries such as plastic molding, die-casting, rubber tires, rollers, chemical reactors, bonding, and internal mixing. In a broad sense, it is called temperature control equipment, which includes temperature control in two aspects: heating and freezing.

Mold Temperautre Controller Products Specification

| Model | Heating Transfer Medium | Max.Temp. | Power Supply | Heating Power(KW) | Pump power(KW) | Inlet/Outlet Diameter | Dimension(mm) | Weight(KG) |

| OMC-6KW-W | Water | 100℃ | 3PH-380V-50Hz | 6 | 0.37 | 1/2“ x 2 | 650x400x650 | 45 |

| OMC-9KW-W | 9 | 0.37 | 1/2“ x 3 | 750x400x760 | 65 | |||

| OMC-12KW-W | 12 | 0.75 | 1/2“ x 4 | 750x400x760 | 70 | |||

| OMC-18KW-W | 9x2 | 0.75 | 1/2“ x 4 | 950x450x850 | 90 | |||

| OMC-24KW-W | 12x2 | 1.5 | 1/2“ x 4 | 950x450x850 | 100 | |||

| OMC-6KW-O | Oil | 180℃ | 6 | 0.37 | 1/2“ x 2 | 650x450x850 | 45 | |

| OMC-9KW-O | 9 | 0.37 | 1/2“ x 3 | 750x400x760 | 65 | |||

| OMC-12KW-O | 12 | 0.75 | 1/2“ x 4 | 750x400x760 | 70 | |||

| OMC-18KW-O | 9x2 | 0.75 | 1/2“ x 4 | 950x450x850 | 90 | |||

| OMC-24KW-O | 12x2 | 1.5 | 1/2“ x 4 | 950x450x850 | 100 |

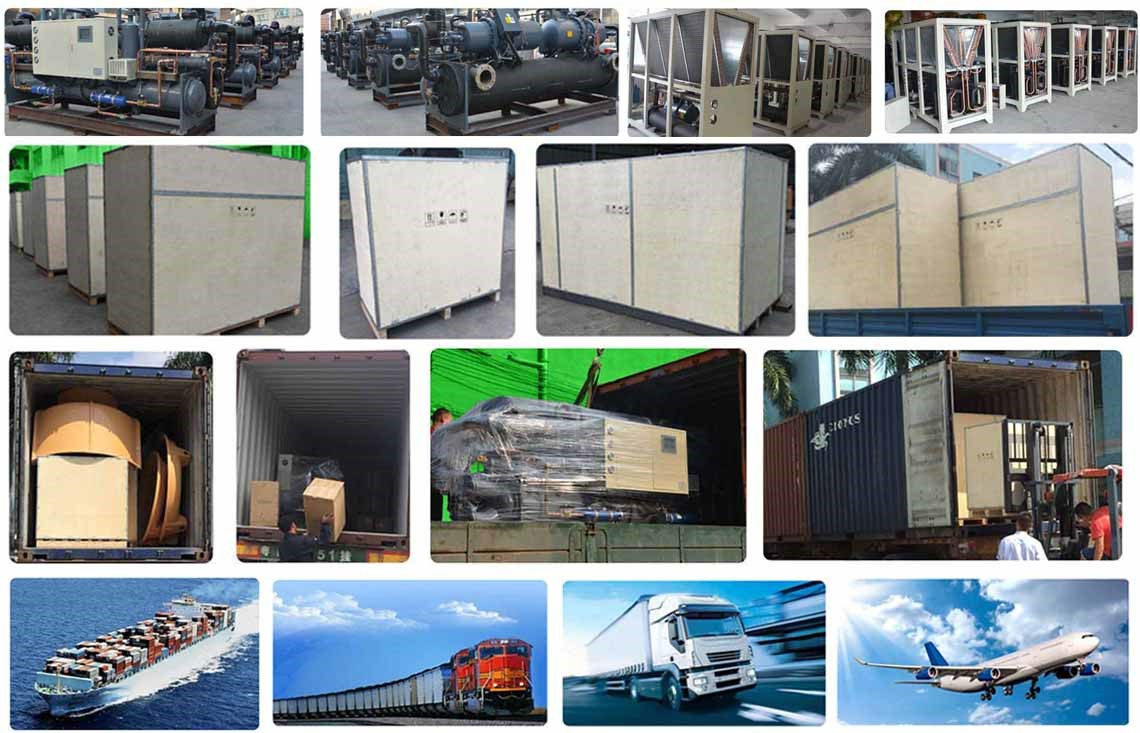

Packing & Shipping

FAQ

Q1: Could you help us to recommend the model for our project?

A1: Yes, we have engineer to check the details and make the scheme for you. Based on the following:

1)Cooling capacity;

2)chilled water inlet and outlet temperature

3)chilled water flow

4) Refrigerant;

5) Ambient temperature;

6)Voltage;

7) Be used for what industry?

8)Any other special requirements?

Q2: How to ensure your product with good quality?

A2: All our products with CE certificate. And use the well-know brand accessories, such as copeland, danfoss,Hanbell, Bitzer compressor Emerson expansion Valve, Siemens controller.

also can be customized. All OUMAL Chillers are factory tested under load conditions to ensure good quality and easy installation for users

Q3: What's the warranty?

A3: 15 months warranty for free if confirmed by both side damage in the quality reason.

Q4: Whats your payment term?

A4: We accept T/T, LC, Western Union, etc. Normally, 30% deposit for production, 70% balance before shipment.

Q5: Are you a manufacturer?

A5: Yes, we have more than 15 years in water chiller business. Also have patent on the water chiller appearance.

The control box design make the unit safety and stably.

Q6: How can i Place an order

A6: Click Below to fill the table or Call 0086 15112554736

en

en es

es