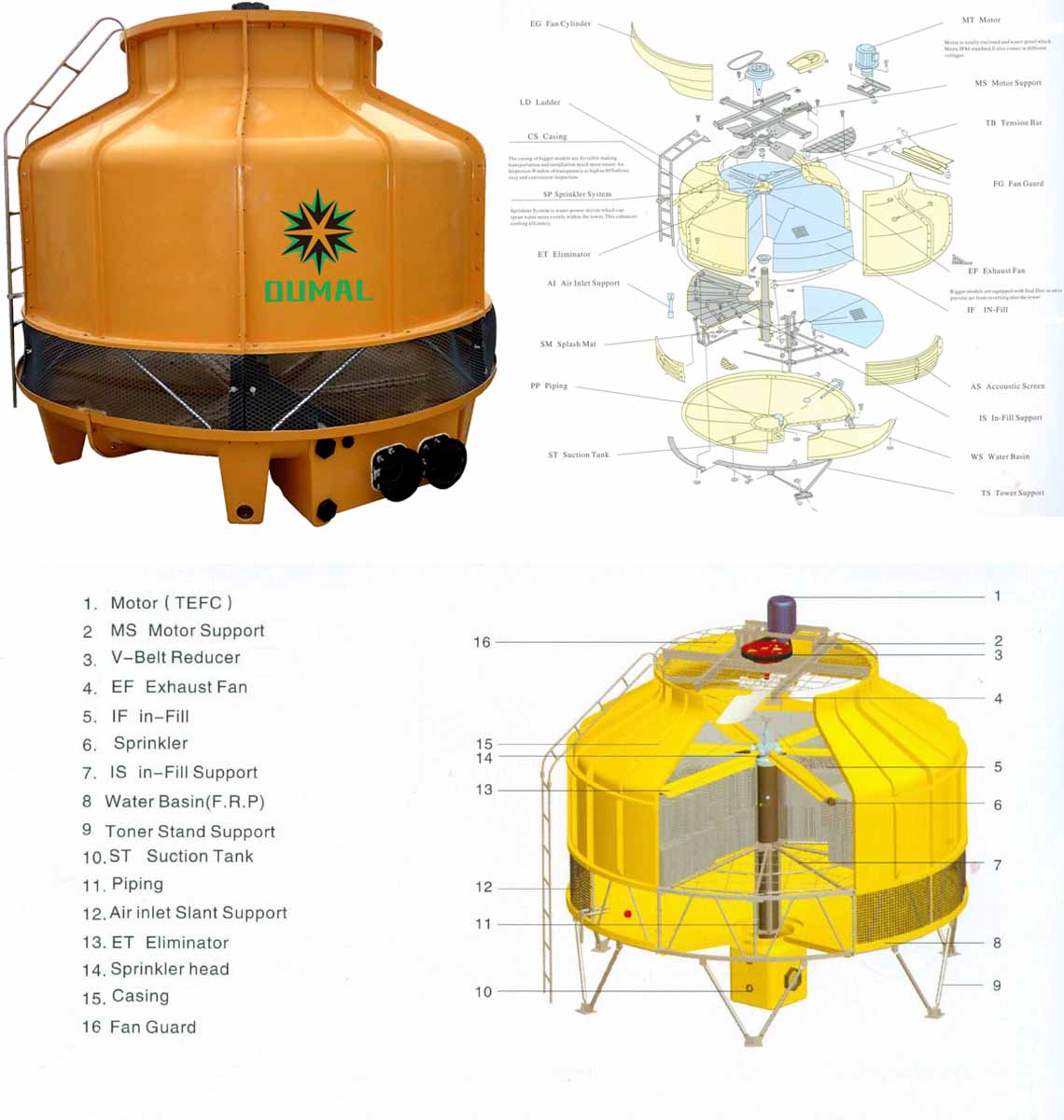

100 Ton Counter Flow cross flow cooling tower

Cooling tower are widely used in cooling water circulation industries such as central AC, frozen warehouse, chemicals , metallurgy plating, etc. The cooling film adopt curvilinear twill design, thus efficiently extends the contact and heat exchange between water circulation and cooling air in the tower, to make air flow in the tower more rational and air resistance reduced to a minimum. Meanwhile, the fan adopts special shaped wind blade design, it means more stable for operation, resulting in lower noise and high cooling efficiency. The shell of cooling tower is refined by excellent high strength glass steel, it keeps fresh against erosion caused by natural factors and chemicals. All steel structures are processed through hot-dip galvanizing, in which way leads to antioxidant and anti-corrosion , and the tower would be more durable.

High-quality cooling tower designed & manufactured by OUMAL features some outstanding advantages as below:

1. Our cooling tower is a compact design, high cooling efficiency and occupies little installation space.

2. Perfect cooling performance than regular cooling towers with small electricity consumption to save your money.

3. The FRP cooling tower is corrosion-resistant, high strength, lightweight, small volume, small occupation area, beautiful and durable, and convenient for transportation, installation, and maintenance.

4. The glass fiber reinforced plastic cooling tower adopts counter flow type air heat exchange technology, and the filler adopts a high-quality modified perchloroethylene wave plate to diffuse the water spraying area; by rotating the water distribution, the water distribution is uniform and the cooling effect is enhanced.

5. The cooling tower body features reasonable profile, stable air flow, excellent material, bright color, UV resistant agent contained in the surface coating resin, aging resistant, high strength, lightweight, corrosion resistance.

6. The cooling tower filling film: it adopts a modified PVC wave plate, which increases ribs horizontally, has strong water redistribution ability, small resistance, good thermal performance, high-temperature resistance of 70 degrees, low temperature – 50 degrees, and good fire resistance.

As a professional cooling tower manufacturer for over 20 years, products of OUMAL are divided into a circular counter flow cooling tower, a square counter flow cooling tower, a square cross flow cooling tower, a non-filler spray cooling tower, a concrete steel cooling tower and a large FRP cooling tower.

The cooling tower series products produced by our factory are corrosion-resistant, high strength, lightweight, small size, small footprint, beautiful and durable, and convenient for transportation, installation, and maintenance.

Therefore, our cooling tower is widely used in all sectors of industries, such as air conditioning, refrigeration, air compression station, heating furnace, condensation process, and other cooling water cycle systems.

Cooling tower quick details

- Cooling capacity 5Ton to 1500Ton

- Water flow rate to 1580m³/Hour

- Cooling efficiency and energy saving

- Counter flow/cross flow type cooling tower available

- High quality and long service life

- Easy installation and operation

- Convenient maintenance save your cost

- 15 months warranty time

Cooling Tower Application

Cooling towers are mainly used in air conditioning cooling systems, refrigeration series, injection molding, tanning, foaming, power generation, steam turbines, aluminum profile processing, air compressors, industrial water cooling and other fields. The most applications are air conditioning cooling, refrigeration, and plastic chemical industries. . The specific division is as follows:

A. Air temperature adjustment category: air-conditioning equipment, cold storage, cold storage room, freezing, heating and cooling air conditioning, etc.;

B. Manufacturing and processing: food industry, pharmaceutical industry, metal casting, plastic industry, rubber industry, textile industry, steel plant, chemical industry, petrochemical products, etc.;

C. Mechanical operation cooling category: generators, steam turbines, air compressors, oil compressors, engines, etc.;

D. Other industries

The role of the cooling tower is to exchange the cooling water carrying waste heat with the air inside the tower body, so that the waste heat is transferred to the air and dispersed into the atmosphere.

100 Ton Cooling Tower Products Specification

| Item Model | OMC | 100 |

| Nominal Flow (Data) | m3/h | 78.1 |

| Air Volume(Data) | CMM | 700 |

| Motor (Data) | KW | 2.25 |

| Noise Level (Data) | DBA | 60 |

| Net Weight (Data) | KG | 500 |

| Running Weight (Data) | KG | 1600 |

| Water inlet ( Piping) | WI | 125 |

| Water outlet ( Piping) | WO | 125 |

| Overflow ( Piping) | OF | 50 |

| Drain ( Piping) | DR | 50 |

| Flow Valve ( Piping) | FV | 20 |

| Tower (Height ) | TH | 2690 |

| Motor (Height ) | MH | 320 |

| Casing (Height ) | CH | 1595 |

| Air inlet(Height ) | AH | 325 |

| Water Basin (Height ) | WH | 450 |

| Water inlet (Height ) | IN | 300 |

| Water outlet (Height ) | OH | 230 |

| Foundation (Height ) | FH | 300 |

| Exhaust Fan (Diameter) | ED | 1450 |

| Water Basin (Diameter) | WD | 2900 |

| Foundation (Diameter) | FD | 2495 |

| Anchor Bolt (Diameter) | BD | 11x6 |

| Foundation (Dimension) | FS | 300 |

| Plate L (Dimension) | PL | 210 |

| Plate W (Dimension) | PW | 130 |

| Suction Tank (Dimension) | BC | 1230 |

| Bolt Center (Dimension) | SC | 180 |

| Flange L (Dimension) | SL | 1430 |

| Type of drive (Material) | Direct | |

| Exhaust Fan (Material) | EF01 | Polycarbonate |

| Motor (Material) | MT02 | T.E.F.C. 380V-3Ph-50Hz |

| Motor support (Material) | MS03 | Galvanized steel |

| Casing (Material) | CS05 | Fibreglass Reinforced Polyester |

| Water Basin (Material) | WB06 | Fibreglass Reinforced Polyester |

| Sprinkler system (Material) | SP08 | Polycarbonate & P.V.C. Pipe |

| Eliminator (Material) | ET10 | Fibreglass Reinforced Polyester |

| Air inlet support (Material) | AI11 | Polycarbonate & P.V.C. Mesh |

| Tower support (Material) | TS12 | Fibreglass Reinforced Polyester |

| Piping (Material) | PP14 | P.V.C. Pipe |

| In-fill support (Material) | IS15 | Polycarbonate Poly & G.1.Steel |

| In-fill (Material) | IF16 | P.V.C. Film |

Package & Shipping

FAQ

Q1: Could you help us to recommend the model for our project?

A1: Yes, we have engineer to check the details and make the scheme for you. Based on the following:

1)Cooling capacity;

2)chilled water inlet and outlet temperature

3)chilled water flow

4) Refrigerant;

5) Ambient temperature;

6)Voltage;

7) Be used for what industry?

8)Any other special requirements?

Q2: How to ensure your product with good quality?

A2: All our products with CE certificate. And use the well-know brand accessories, such as copeland, danfoss,Hanbell, Bitzer compressor Emerson expansion Valve, Siemens controller.

also can be customized. All OUMAL Chillers are factory tested under load conditions to ensure good quality and easy installation for users

Q3: What's the warranty?

A3: 15 months warranty for free if confirmed by both side damage in the quality reason.

Q4: Whats your payment term?

A4: We accept T/T, LC, Western Union, etc. Normally, 30% deposit for production, 70% balance before shipment.

Q5: Are you a manufacturer?

A5: Yes, we have more than 15 years in water chiller business. Also have patent on the water chiller appearance.

The control box design make the unit safety and stably.

Q6: How can i Place an order

A6: Click Below to fill the table or Call 0086 15112554736

en

en es

es